Description

T10 steel is composed of simple iron and carbon. Low alloyed high-strength steels incorporate small amounts of other elements (usually < 2% by weight).

So it can provide extra strength.

T10 Steel Worldwide Equivalents

| / | China | Kr | Germany | Japan | Sweden | England |

| Standard | GB | KS | DIN,WNr | JIS | SS | BS |

| Grade | T10 | STC3/STC4 | 1.1645 C105W2 | SK105/SK95 | 1880 | 1407 |

| / | Italy | Spain | USA | Russia | France | IOS |

| Standard | UNI | UNE | AISL/SAE/ASTM | roct | AFN0R/NF | – |

| Grade | C9SKU/C100KU | F. 515/F. 516 | W1-91/2/172301 | Y10 | Y1105/C105E2U | TC105 |

T10 Steel Chemical Composition

| C | Si | Mn | S | P |

| 0.95-1.04 | ≤0.35 | ≤0.40 | ≤0.03 | ≤0.035 |

Heat Treatment

Normalizing

Normalizing temperature 830~850°C. Air-cooled, hardness 255~321HBW.

Ordinary annealing

Annealing temperature 750 ~ 760°C. Keep warm for 2 ~ 4h, and then cool to 500 ~ 600°C at a cooling rate of <30’C/h, and air-cooled.

Isothermal spheroidizing annealing

1) 750~760°C×2~4h. 680~700°C×4~6h. The furnace is cooled again to 5m ~ 600°C, and it is air-cooled. Hardness≤207HBW.

2) 750~770°C ×1~2h, 680~700°C ×2 ~3h, hardness 163~207HBw, pearlite grade 1~5

Features and Application

T10 is the most common carbon tool steel. Moderate toughness, low production cost. After heat treatment, the hardness can reach above 60HRC. But, this steel has low hardenability and poor heat resistance (250°C). It is not easy to overheat during quenching and heating and still maintains fine grains. The toughness is acceptable, and the strength and wear resistance are higher than those of T7-T9. But, the hot hardness is low, the hardenability is still not high, and the quenching deformation is large.

T10 steel is suitable for making various tools. Such as turning knives, planning knives, drills, taps, reaming tools, screw dies, milling cutters, and saw blades. It can also make cold heading dies, punching dies, wire drawing dies, cold extrusion dies for aluminum alloys, paper blanking dies, plastic forming dies, small-sized cold trimming dies and punching dies, low-precision and simple-shaped measuring tools ( such as cardboards.). It can also be used as wear-resistant parts that are not subject to large impacts.

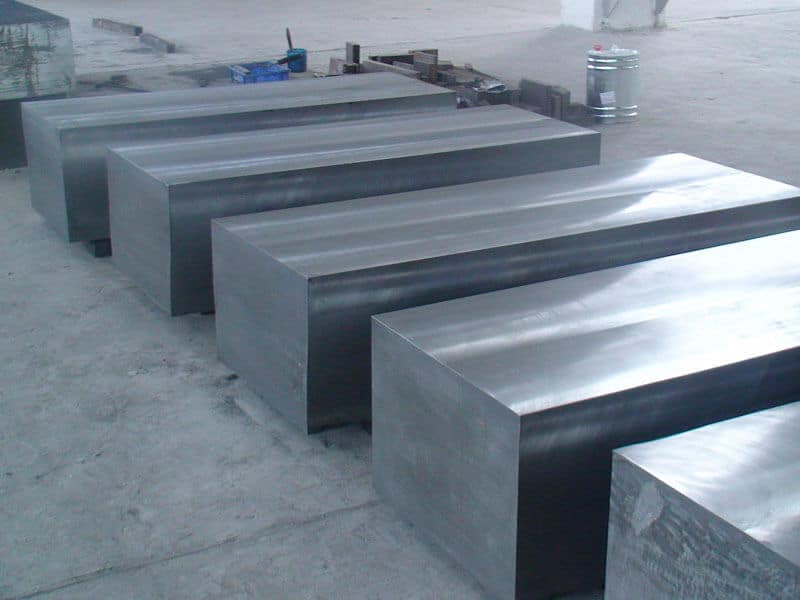

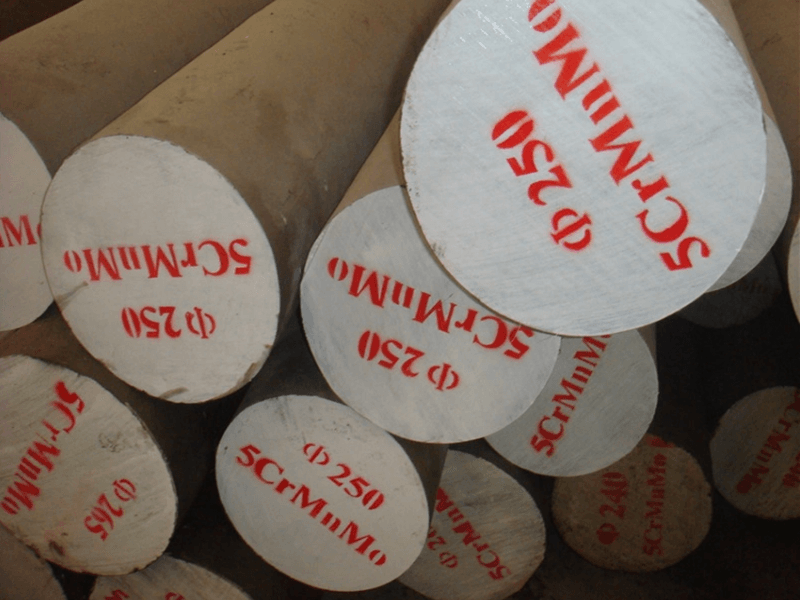

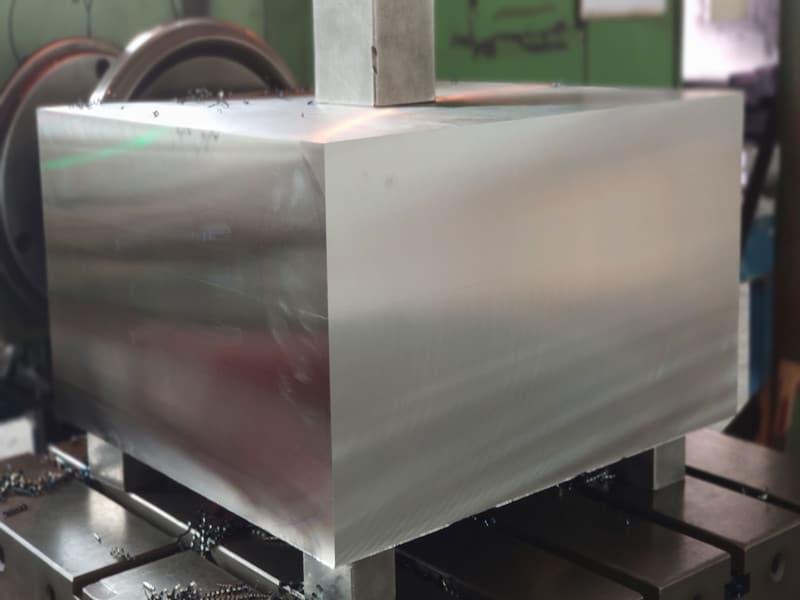

T10 products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |