Description

6W6Mo5Cr4V die steel is low-carbon high-speed die steel. Compared with W6Mo5Cr4V2, the mass fraction of carbon is reduced by 0.21%. The mass fraction of vanadium is reduced by 1.05%–1.11%. The inhomogeneity of carbides is significantly improved. The bending strength and plasticity are increased by 30%~50%. The impact toughness is increased by 50%~100%.

6W6Mo5Cr4V Chemical Composition

| C | Si | Mn | P | S | Cr | Ni | Mo | V | W | Cu |

| 0.55~0.65 | ≤0.40 | ≤0.60 | ≤0.030 | ≤0.030 | 3.70~4.30 | ≤0.20 | 4.50~5.50 | 0.70~1.10 | 6.00~7.00 | ≤0.30 |

6W6Mo5Cr4V Mechanical Properties

| Proof strength Rp0.2(MPa) | Tensile strength Rm(MPa) | Impact energy KV(J) | Elongation at fracture A(%) | Reduction in Cross-section on fracture Z(%) | As-Heat-Treated Condition | Brinell hardness(HBW) |

| 472(≥) | 749(≥) | 33 | 32 | 23 | Solution and Aging, Annealing, Ausaging, Q+T | 431 |

6W6Mo5Cr4V Physical properties

| Property | Density kg/dm3 | Temperature T °C/F | Modulus of elasticity kN/mm2 | Temp. °C/°F |

| 519(≥) | 564(≥) | 14 | 324 | 198 |

| Specific heat J/kgK | Thermal conductivity W/mK | Electric resistance µΩ·cm | Creep strain limit (10000h) (Rp1,0)N/mm2 | Creep rupture strength (10000h) (Rp1,0)N/mm2 |

| 41 | 14 | Solution and Aging,Annealing, Ausaging,Q+T | 862 | 597 |

Heat Treatment

Forging Process

6W6Mo5Cr4V mold steel has a narrow forging temperature range due to its high molybdenum content. The forging process is: the heating temperature is 1100~1140℃. The initial forging temperature is 1050~1100℃. The final forging temperature is 800~900℃.

The forging deformation resistance of 6W6Mo5Cr4V mold steel is relatively large.

Annealing process

6W6Mo5Cr4V mold steel is annealed after forging.

The ordinary spheroidizing annealing process: heating to 850~860℃ for 1~2h, cooling to 550℃ and then air cooling;

The isothermal spheroidizing annealing process: heating to 850~860℃ for 1~2h. The furnace is cooled to 740~750℃ and then kept for 3~4h. After the furnace is cooled to 550 ℃, it is air-cooled and the annealing hardness is 197~255HBS.

Quenching and tempering process

To get good toughness and higher wear resistance, lower and higher temperature tempering are usually used.

The process parameters: heating to 1180~1200℃ for quenching, 560~580℃. Temper three times. Every 1.5h, the hardness is 69~63HRC.

Features and Application

6W6Mo5Cr4V mold steel can be used to replace high-speed mold steel and high-carbon and high-chromium mold steel. It can be used to manufacture cold extrusion punches or cold heading punches for steel materials. The service life can be increased by 2 to 10 times.

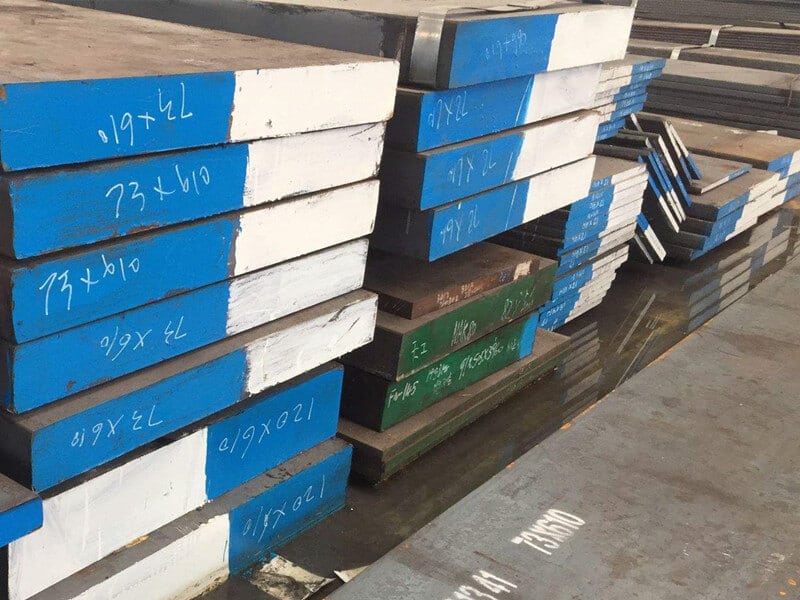

6W6Mo5Cr4V Steel products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |