Description

6Cr4W3MoVNb mold steel is niobium-containing matrix steel. The contents of alloying elements Cr, W, Mo and V in the steel are designed from the matrix composition of the quenched W6Mo5Cr4V3 high-speed steel. The role of alloying elements in the die is like that in high-speed steel.

6Cr4W3MoVNb Chemical Composition

| C | Si | Mn | Cr | W | Mo | V |

| 0.60-0.70 | ≤0.40 | ≤0.40 | 3.80-4.40 | 2.50-3.50 | 1.80-2.50 | 0.80-1.20 |

6Cr4W3MoVNb Process

Forging process

6Cr4W3MoVNb mold steel is a Lay-type body and needs to be forged. The forging properties of 6Cr4W3MoVNb mold steel are good. But it should be heated slowly to ensure that it burns through. The forging heating temperature is 1120~1150℃. The temperature for starting forging is 1100℃, and the temperature for ending forging is 850~900℃. Cool slowly.

Annealing process

The annealing process of 6Cr4W3MoVNb mold steel includes conventional spheroidizing annealing and isothermal spheroidizing annealing.

The conventional annealing process is 800 ° C, heating for 3~4 hours. Slowly cooling to 500 ° C before releasing.

The isothermal spheroidizing annealing process is heating at 860°C for 3~4h. Cooling to 740°C for isothermal 5~6h. And furnace cooling to 500°C for release. The hardness after annealing is 217HBS. If the isothermal time is extended from 6h to 9h, the hardness is further reduced to 187HBS.

It can be formed by cold extrusion, which is the biggest advantage of 6Cr4W3MoVNb mold steel.

Quenching and tempering process

The quenching temperature of 6Cr4W3MoVNb mold steel is 1080~1180℃. The quenching heating time should ensure that the carbides are fully dissolved and homogenized. At the same time, the grains are not grown. The heating coefficient in the salt bath furnace is preferably 15~20s/mm.

According to the shape of the mold and the requirements for deformation, the cooling methods can be oil cooling, oil quenching-air cooling and graded quenching. 6Cr4W3MoVNb mold steel generally adopts secondary tempering. The tempering temperature range is 520~560℃.

Application

- 1. Manufacture of cold extrusion dies, screw punches, cold punching dies, drawing dies and thread rolling plates.

- 2. Manufacture of cold work die with impact load and complex shape. Such as cold heading dies, screw punches.

- 3. Cold extrusion punch for steel parts. Choose hardness 62 ~ 64HRC.

- 4. Make large and complex molds with large impact loads.

- 5. It is used for cold working die steel such as cold extrusion, warm extrusion, cold punching, cold heading and cold shearing. The service life is doubled compared to the original high-speed steel and high-carbon tool steel.

- 6. Make large and medium-sized cold heading dies and precision stamping dies.

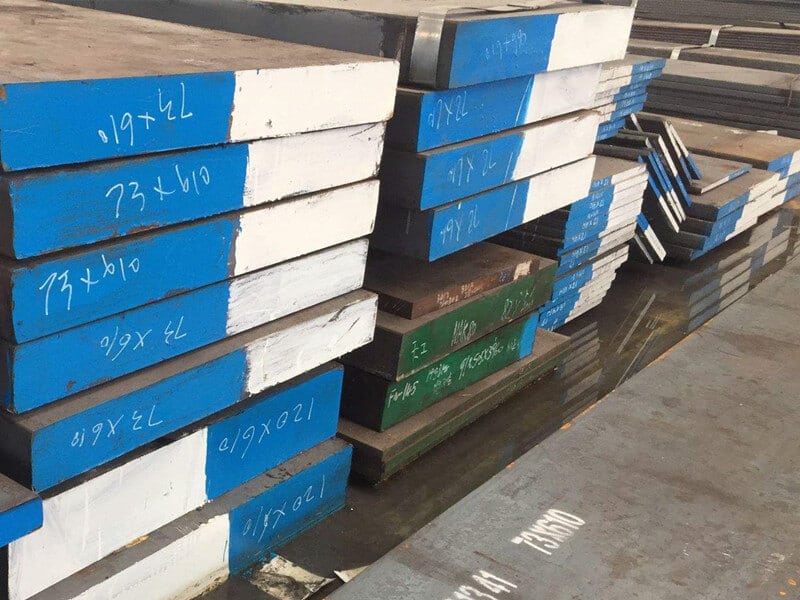

6Cr4W3MoVNb products

| Product type | Products | Dimension | Processes | Delivery Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |