Description

3Cr3Mo3W2V steel is hot work die steel. Its cold working and hot working properties are good. The quenching and tempering temperature range is wide. It has high thermal strength and thermal fatigue properties. It also has good wear resistance and anti-tempering stability.

3Cr3Mo3W2V Steel Chemical Composition

| C | Si | Μn | Cr | Mo | W | V | P | S |

| 0.32~0.42 | 0.60~0.90 | ≤0.65 | 2.80~3.30 | 2.50~3.00 | 1.20~1.80 | 0.80~1.20 | ≤0.03 | ≤0.03 |

3Cr3Mo3W2V Steel Mechanical Properties

| Proof strength Rp0.2(MPa) | Tensile strength Rm(MPa) | Impact energy KV(J) | Elongation at fracture A(%) | Reduction in cross section on fracture Z(%) | As-Heat-Treated Condition | Brinell hardness(HBW) |

| 273(≥) | 789(≥) | 33 | 34 | 34 | Solution and Aging,Annealing, Ausaging,Q+T | 123 |

3Cr3Mo3W2V Steel Physical properties

| Property | Density kg/dm3 | Temperature T °C/F | Specific heat J/kgK | Thermal conductivity W/mK |

| 753(≥) | 576(≥) | 31 | 31 | 24 |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0)N/mm2 | Creep rupture strength (10000h) (Rp1,0)N/mm2 | Electric resistance µΩ·cm | Modulus of elasticity kN/mm2 |

| 676 | 679 | 238 | Solution and Aging,Annealing, Ausaging,Q+T | 333 |

Heat Treatment

Annealing

Generally, annealing adopts 780-800 degrees, heat preservation for 4-6 hours, cooling to 550 degrees at ≤50 degrees/hour, air cooling, isothermal annealing uses 700-800 degrees heat preservation 2-4 sales, and then 670-720 degrees heat preservation, keeping 2-4 hours, cooling to 500 degrees at a cooling rate of ≤50 degrees/hour, air cooling, annealing hardness 241-197H

Forging

Oil-quenched die steel has some crack sensitivity. It is not suitable to heat rapidly during forging heating. It is best to perform a preheating at 650-750 degrees. The forging heating temperature is 1130-1150 degrees, and the final forging temperature should be greater than 800-850 degrees. The upper limit temperature is used when the steel ingot is forged. The lower limit temperature is taken when the blank is forged

Application

3Cr3Mo3W2V steel is suitable for making hot working dies such as upset forging and press forging. The service life of the mold is high.

- The thickness is not more than 2MM thin plate. Efficient blanking dies, punching dies and stamping dies.

- Various scissors, inlaid blades, woodworking blades.

- Thread rolling die and wear-resistant slider.

- Cold heading mold, thermosetting resin molding mold.

- Deep drawing die, cold extrusion die.

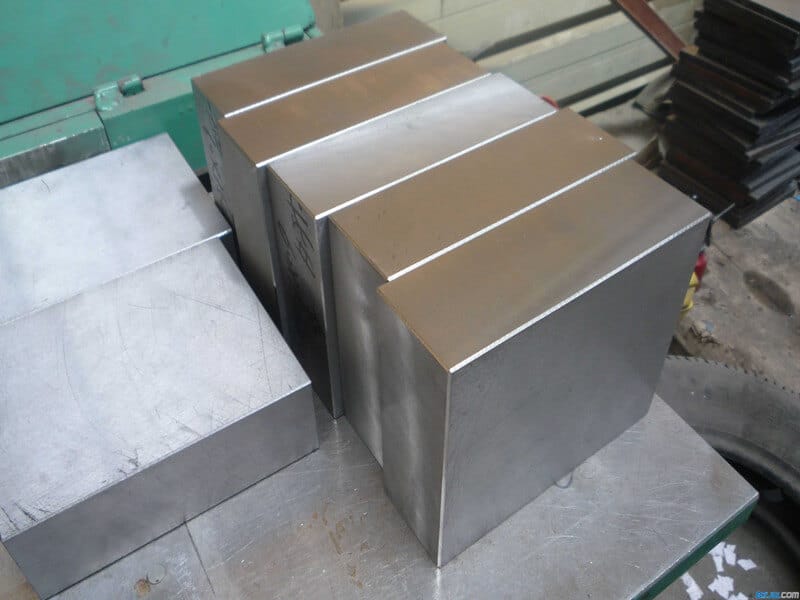

3Cr3Mo3W2V products

| Product type | Products | Dimension | Processes | Delivery Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |