2A12 Aluminum Sheet

- Thickness: 1.0-500mm

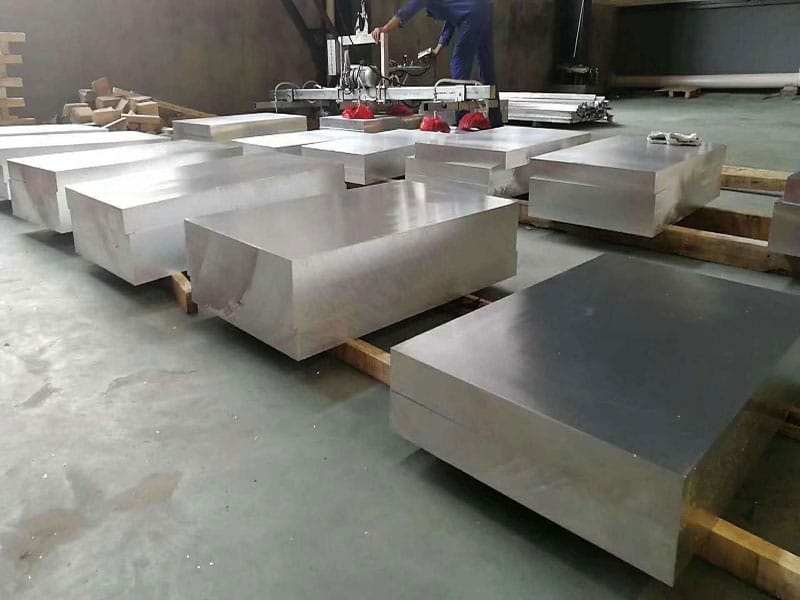

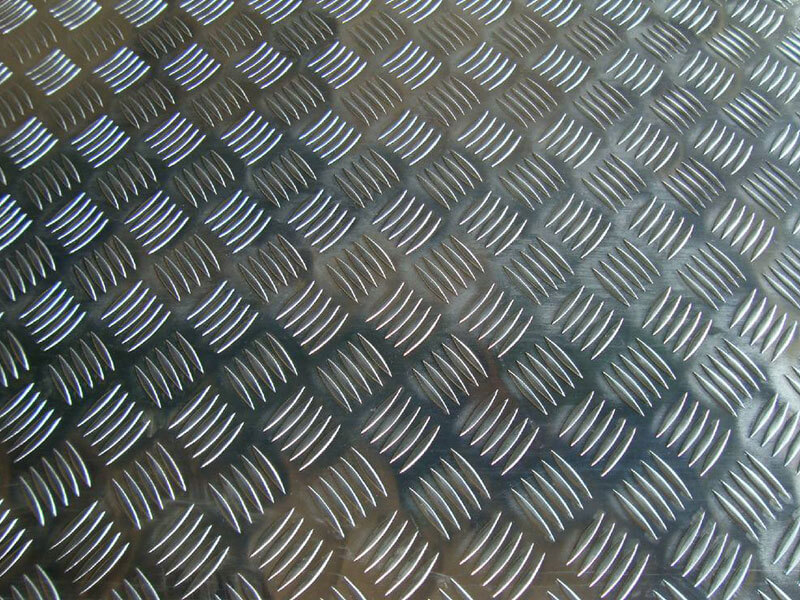

- Applications: Dies, high-strength parts, thick plates, heavy forgings

WhatsApp for Price: + 86 189 5460 7915

Description

2A12 aluminum sheet is a 2 series AL-CU alloy. It mainly contains alloy component Cu and belongs to the heat treatment alloy plate. So, 2A12 aluminum plate has higher strength after heat treatment.

2A12 aluminum plate has good machinability and spot welding performance. But it is easy to produce intergranular cracks in Gas metal arc welding and argon arc welding. And corrosion resistance is not high. To improve its corrosion resistance,, it needs surface treatment or aluminum plating.

JC Metal China is a 2000 Series Aluminum Sheet Supplier. The main type is 2014,2017,2024,2A11,2A12,2A14 aluminum sheet.

2A12 aluminum sheet Chemical Composition

| Si | Cu | Mn | Ti | Fe | Ni | Mg |

| ≤0.50 | 3.8-4.9 | 0.30-0.90 | ≤0.15 | 0.00-0.500 | ≤0.10 | 1.2-1.8 |

2A12 Aluminum Plate characteristics

2A12 aluminum alloy plate is a kind of high-strength hard aluminum. It can be strengthened by heat treatment.

When 2A12 aluminum plate is annealed, just quenched and hot, its plasticity is moderate.

Spot welding has good weldability. There is a tendency to form intergranular cracks when using gas welding and argon arc welding.

The machinability of 2A12 aluminum plate is still good after quenching and cold work hardening.

Poor in the annealed state. The corrosion resistance is not high.

Anodizing and painting methods are often used, or the surface is coated with aluminum to improve corrosion resistance.

Uses

2A12 aluminum plates are mainly used to make various high-load parts and components. But not stamping forgings. Such as plane skeleton parts, skins, bulkheads, ribs, spars, rivets and other working parts below 150°C.

It is mostly used in molds, transportation vehicles, compressors, rivets, truck wheel hubs, propeller components and various other structural parts.

2A12 aluminum plate Mechanical Properties

| Tensile strength σb (MPa) | ≥410 |

| Conditional yield strength σ0.2(MPa) | ≥265 |

| Elongation δ5(%) | ≥12 |

Sample size: bar diameter (square bar, hexagonal bar inscribed circle diameter)≤22 2A12 heat treatment

Note: Longitudinal mechanical properties of Bar at room temperature

2A12 Heating Treatment

Homogenization annealing

The heating temperature is 480 ~ 495 °C. The holding time is 12 ~ 14h, the furnace is cold.

Heating temperature 390 ~ 430 °C, holding time 30 ~ 120 min, furnace cooling to 300 °C, Air cooling.

Rapid annealing

Heating temperature 350 ~ 370 °C, holding time 30 ~ 120 min, Air cooling.

Quenching and aging

Quenching temperature 495 ~ 505 °C, water-cooling. Artificial aging 185 ~ 195 °C, 6 ~ 12 h. Air-cooling; natural aging: room temperature 96 H.

2A12 Aluminum Plate Price

- JC Metal China 2A12 Aluminum Sheet price = Ingot Cost/Raw aluminum cost + Processing cost.

- 2A12 Aluminum Sheet unit price is $/ton,$/kg,$/Pound,$/lbs.

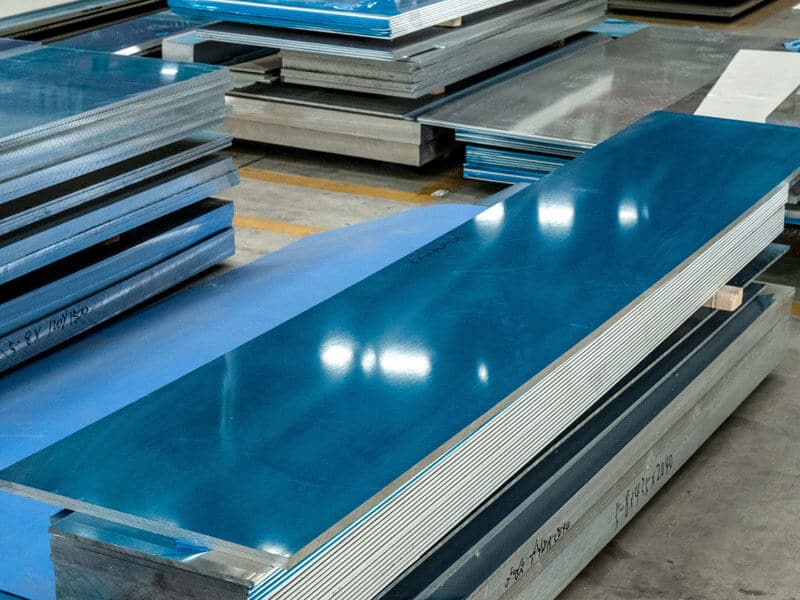

- 2A12 Aluminum Sheet price will be different as per the below factors. Such as Length, Width, Thickness, State, Surfaces Treatment.

- Business Term: FOB,CFR,CIF,DDP,DUP…

- Payment Term: TT.LC.TT+LC…

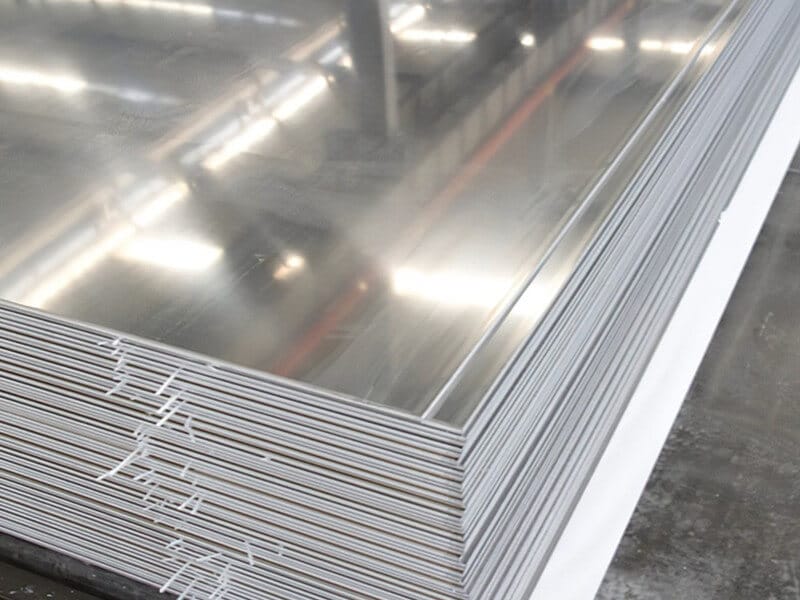

Packing

1–Install wooden pallets. Use steel belts to reinforce them to avoid collisions during transportation.

2–Can be packed as per customer’s requirements.

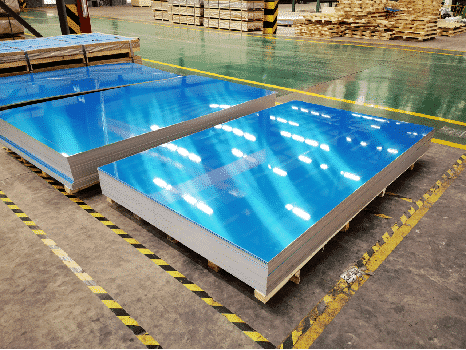

Aluminum Sheet Plate Before Packing

Aluminum Sheet Plate After Packing

Aluminum Sheet Container Loading

2A12 aluminum plate Technical Parameters

| Alloy Name | 2A12 aluminum plate , 2A12 aluminum sheet |

| Material State | F、O、T3、T4、T351、H112 |

| Thickness | 1mm-600mm |

| Width | 500mm-2650mm |

| Length | 500mm-16000mm |

| Typical applications | Molds, high-strength parts |

Market application

It is mostly used in molds, transportation vehicles, compressors, rivets, truck wheel hubs, propeller components and various other structural parts.