3003 Aluminum Foil

- Thickness: 0.006-0.2mm

- Application: Electronic foils, honeycomb materials, building sound insulation materials, food packaging

WhatsApp for Price: + 86 189 5460 7915

Description

3003 Aluminum Foil is an Al-Mn series alloy. Due to the addition of alloy Mn element, it has excellent rust resistance, weldability, corrosion resistance.

3003 aluminum foil alloy cannot be strengthened by heat treatment. Need to use cold working methods to improve its mechanical properties. The medium strength 3003 aluminum foil is 10% stronger than the 1 series alloy aluminum foil.

The plasticity and welding performance of 3003 aluminum foil is also very good. So, it is an ideal choice for electrolytic capacitor aluminum foil, lunch box container, and aluminum honeycomb core material. 3003-H18 aluminum foil, 3003-O aluminum foil, 3003-H24 aluminum foil and other 3003 aluminum foil products are food-grade. They are with clean degreasing, few pinholes, good plate shape, no deformation during cutting, and easy peeling.

Chemical Composition

| Si | Cu | Mg | Zn | Mn | Ti | Fe |

| 0.6 | 0.05-0.2 | — | 0.10 | 1.0-1.5 | — | 0.7 |

Characteristics

1. High Corrosion resistance. Al2O3 protective film easily formed on the surface of 3003 aluminum foil. Can resist the corrosion of most acids and organics

2. High Security. Non-toxic, tasteless, safe and hygienic. Aluminum foil is widely used as packaging material after compounding, printing and gluing.

3. High plasticity. In the annealed state, 3003 aluminum foil has high plasticity. Suitable for semi-cold hardening. But the plasticity is the lowest when it is cold hardened.

4. Good ductility. Compared with 1 series and 8011 aluminum foil, It has better processing performance and elongation. Strong comprehensive performance.

Mechanical Properties

| Tensile strength σb (MPa) | 140-170mpa |

| Yield Strength σ0.2 (MPa) | ≥85 |

| Elongation δ16 (%) | ≥9% |

| Hardness(HB) | 48 |

3003 Aluminum Foil Price

- JC Metal China 3003 Aluminum Foil price = Ingot Cost/Raw aluminum cost + Processing cost.

- 3003 Aluminum Foil unit price is $/ton,$/kg,$/Pound,$/lbs.

- 3003 Aluminum Foil price will be different as per the below factors. Such as Length, Width, Thickness, State, Surfaces Treatment.

- Business Term: FOB,CFR,CIF,DDP,DUP…

- Payment Term: TT.LC.TT+LC…

Packing

- Core Diameter: 405mm or 505mm

- Protective Film:The film with the customer’s trademark can be customized according to customer requirements.

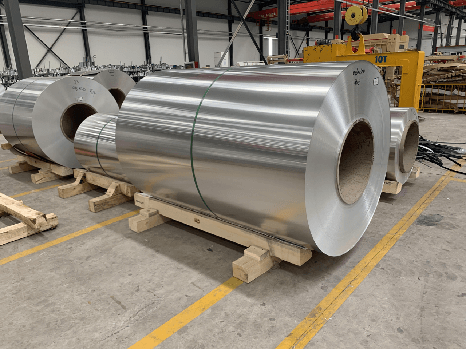

Before Packing

After Packing

Container Loading

Technical parameters

| Products | Type | Temper | Thickness(mm) | Width (mm) | Length(mm) |

| 3003 Household Foil | Painted, | H111 H12 H14 H16 H18 H22 H24 H26 H28 | 0.01-0.2 | 300-1100 | Customized |

| 3003 Container Foil | Bare, Mill Finish | H22 H24 | 0.01-0.2 | 200-1100 | Customized |

| 3003 Packaging Foil | Tread plate | O H22 H24 | 0.018-0.2 | 100-1600 | Customized |

| 3003 Electronic Foil | H18 | 0.02-0.055 | 100-1600 | Customized |

Stock information

| Specifications(mm) | Status |

| 0.05*280*C | H24 |

| 0.045*300*C | H18 |

| 0.036*590*C | H19 |

| 0.084*374*C | H24 |

| 0.038*590*C | H19 |

| 0.035*315*C | H18 |

Market Applications

Construction industry: roofs, wall panels, soundproof ceilings and corrugated panels.Chemical industry: Metal working equipment for storage tanks, pipes, jackets, HVAC.Food industry: all kinds of lunch boxes and food packaging.

Electrolytic capacitor foilLIke 3003-H18 aluminum foil, 3003-O aluminum foil, 3003-H24 aluminum foil. They have excellent corrosion resistance and rust resistance. It can meet the performance requirements of various electrolytic capacitor cathode materials.

Lunch box container foil3003 aluminum foil has good elongation and processability. It can well meet the strength requirements of the food box container during stamping. Especially for the complicated and special-shaped structure of three-cavity or multi-cavity containers. After proper annealing treatment, the yield rate of 3003-h24 aluminum foil lunch box containers can reach 95%.

Aluminum honeycomb core material3003-h18 aluminum foil is used as the base material of honeycomb panels. Processed into dense I-beam. The scattered honeycomb panels are compressed in all directions. Make the honeycomb panel evenly stressed.