6061 Aluminum Sheet

- Thickness: 0.3-500mm

- Application areas: mobile phone card slot, mobile phone case, mold, car body, 6061 mask machine

WhatsApp for Price: + 86 189 5460 7915

Description

6061 Aluminum Sheet is an aluminum alloy plate with Si and Mg as the main elements. The content of Mg and Si is 0.8-1.2% and 0.4-0.8%. 6061 aluminum alloy is a very important one in the 6000 series aluminum alloys.

JC Metal can supply 6061-t6 aluminum plate, pre-stretched 6061-t651 aluminum alloy plate, 6061 super flat plate, 6061 quenched plate and other aluminum plates

Uses and advantages of thin 6061 aluminum sheet:

White surface/bright surface. No milling required. Cost-saving. Widely used in 3C fields such as mobile phone card slots, buttons, computer brackets, computer shells, trolley boxes, aluminum furniture, door panels/door handles. 6061 aluminum alloy sheets can be used for 5G mobile phones

Uses and advantages of 6061 medium-thick aluminum plate:

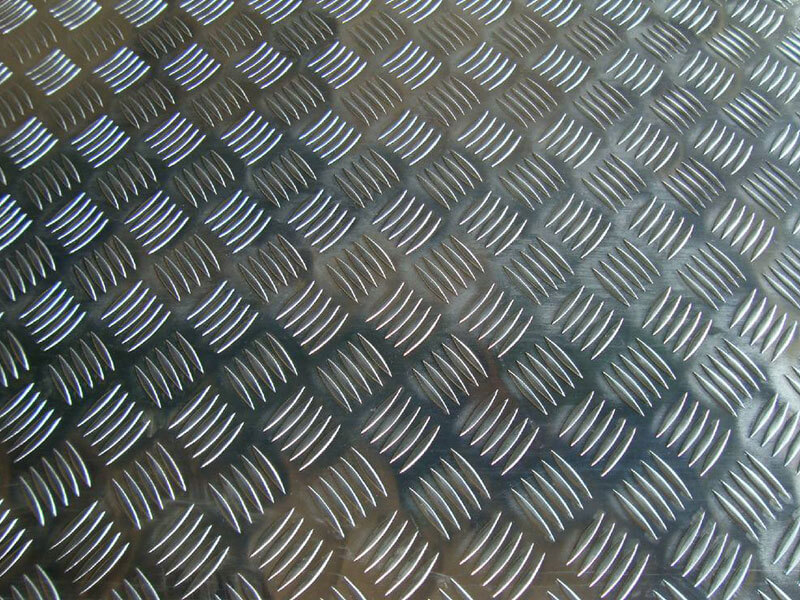

The internal stress is relieved, and the cutting will not deform. It is widely used in underwear molds, shoe molds, precision machining. Passenger car decorative panels/checkered plates, car chassis protection parts, car four doors, two covers, car wheels, car seats.

JC Metal is a 6000 series aluminum sheet supplier. The main type includes 6005,6005A,6060,6061,6063,6082,6101 aluminum sheet.

6061 Aluminum Sheet Chemical composition

| Si | Cu | Mg | Zn | Mn | Ti | Fe | Cr |

| 0.4-0.8 | 0.15-0.40 | 0.8-1.2 | 0.25 | 0.15 | 0.15 | ≤0.70 | 0.04-0.35 |

6061 Aluminum Sheet characteristics

6061 aluminum alloy plates are easy to process and weld, electroplate good toughness.

Not easy to deformation

Easy to polish and surface treatment

Strong corrosion resistance

6061 Aluminum Sheet Mechanical properties

| Tensile strength σb (MPa) | ≥205 |

| Conditional yield strength σ0.2(MPa) | ≥55.2 |

| Elongation δ5(%) | ≥15 |

Specimen Size: all wall thickness

Note: longitudinal mechanical properties of tubes at room temperature

6061 Aluminum Sheet Heating Treatment

Rapid annealing

Heating temperature 350 ~ 410 °C, holding time 30 ~ 120 min depending on material effective thickness. Air or water cooling.

High temperature annealing

The heating temperature is 350 ~ 500 °C, the holding time is 10 ~ 30min when the thickness of the finished product is ≥6mm. Stops after heat penetration when the thickness of the finished product is less than 6mm. Air Cooling.

Low temperature annealing

The heating temperature is 150 ~ 250 °C and the holding time is 2 ~ 3h. Air or water cooling. Homogenization annealing 570 degrees Celsius, seven hours of insulation. Air cooling

6061 Aluminum Sheet price

- JC Metal China 6061 Aluminum Sheet Price price = Ingot Cost/Raw aluminum cost + Processing cost.

- 6061 Aluminum Sheet Price unit price is $/ton,$/kg,$/Pound,$/lbs.

- 6061 Aluminum Sheet Price price will be different as per the below factors. Such as Length, Width, Thickness, State, Surfaces Treatment.

- Business Term: FOB,CFR,CIF,DDP,DUP…

- Payment Term: TT.LC.TT+LC…

Packing

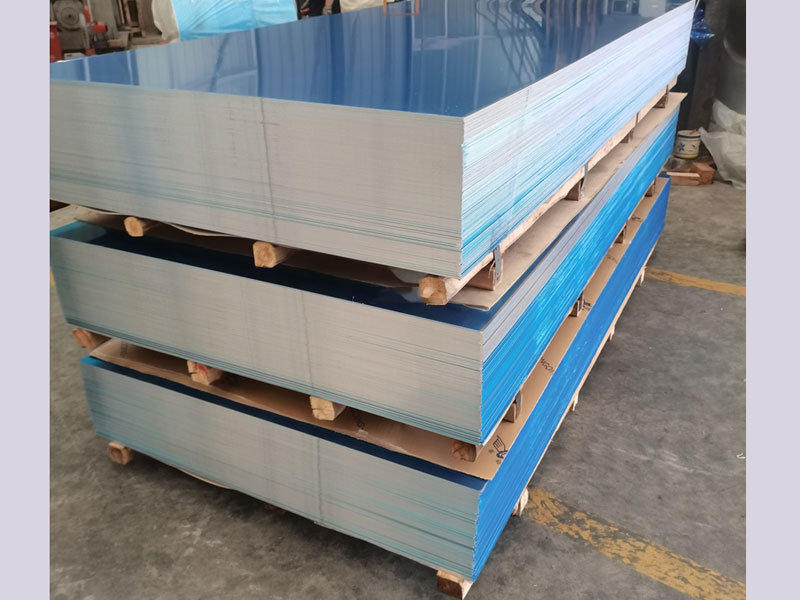

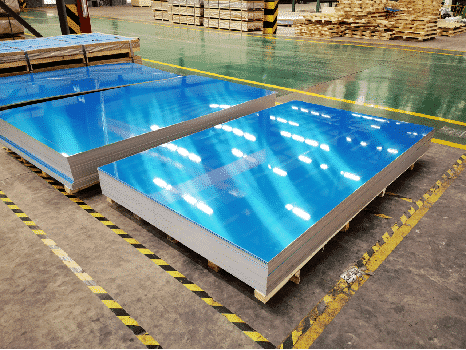

1–Install wooden pallets. Use steel belts to reinforce them to avoid collisions during transportation.

2–Can be packed as per customer’s requirements.

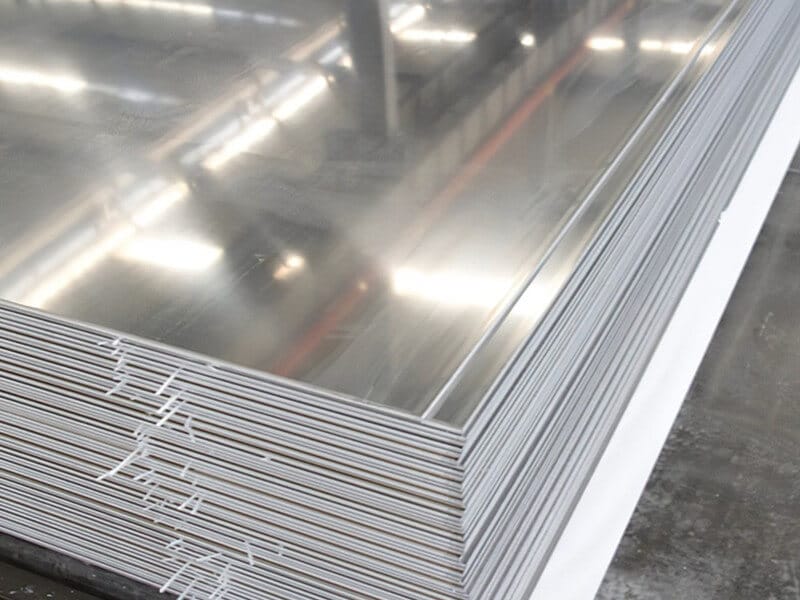

Aluminum Sheet Plate Before Packing

Aluminum Sheet Plate After Packing

Aluminum Sheet Container Loading

Technical parameters

| Typical alloy | 6061 aluminium plate |

| Material State | F,O,T4,T6,T651,H112 |

| Thickness | 0.3mm-500mm |

| Width | 100mm-2800mm |

| Length | 500mm-16000mm |

| Typical products | Mobile phone card slot, mobile phone case, mold, automobile, mask machine, precision machining |

Stock information

| Specifications(mm) | Status |

| 4.24*1250*2500 | T6 |

| 1.0*1220*2440 | T6 |

| 1.0*1220*2440 | T6 |

| 0.8*1220*2440 | T6 |

| 2.97*1220*2440 | T6 |

| 3.97*1220*2440 | T6 |

| 1*1250*2500 | T6 |

| 3.0*1250*2500 | T6 |

| 3.98*1220*2440 | T6 |

Market Applications

The main uses of 6061 aluminum alloy are as follows:

1, Aerospace: plane skin, fuselage frame, inner panels, rotors, propellers, fuel tanks, landing gear.

2. Transportation: Subway cars, accessories, doors, windows, rails, siding, wheels, engine parts.

3. Construction: make doors, windows, curtain walls, aluminum panels.

4. Electronic home appliances: Used in a variety of bus, wire, conductor, electrical components, refrigerators, air conditioning, cables.

5. Packaging: for beverages, food, cosmetics, drugs, cigarettes, industrial products packaging.