3003 aluminum alloy belongs to the 3000 series It is a kind of Mn-Al alloy. Besides Mn, other metal elements include silicon, iron, copper and zinc.

Like other 3000 series aluminum alloys, 3003 aluminum alloys are not heat treatable. It can only be hardened by cold work. Due to the addition of manganese, its strength is higher than that of the 1000 series aluminum alloy. But compared with other heat treatable aluminum alloys, 3003 aluminum has no advantages. it belongs to a medium strength alloy.

Although the strength of 3003 aluminum alloy is not very high, it also has many advantages. The main purpose of this article is to introduce the 3003 aluminum alloy.

3003 aluminum comparison

- Manganese (Mn): 1.0~1.5

- Copper (Cu): 0.05~0.2

- Iron (Fe): 0.7

- Silicon (Si): 0.60

- Zinc (Zn): 0.10

- Aluminum (Al): Balance

Temper Alloy Series

- 3003-F,

- 3003-O,

- 3003-H12,

- 3003-H14,

- 3003-H16,

- 3003-H18,

- 3003-H19,

- 3003-H22,

- 3003-H24,

- 3003-H26,

- 3003-H28,

- 3003-H111,

- 3003-H112,

- 3003-H114

Characteristic

- Weldability: 3003 aluminum alloy has good weldability and can be welded and brazed by all methods.

- Corrosion resistance: The corrosion resistance of 3003 aluminum alloy is very good. Close to the corrosion resistance of industrial pure aluminum. It is good for atmosphere, fresh water, sea water, food, organic acid, gasoline, dilute acid solution and neutral inorganic salt solution corrosion resistance.

- Plasticity: It has high plasticity in the annealed state, good plasticity in semi-cold work hardening. Low plasticity in cold work hardening.

- Machinability: 3003 aluminum alloy is easy to machine and can be machined very well.

3003 aluminum use

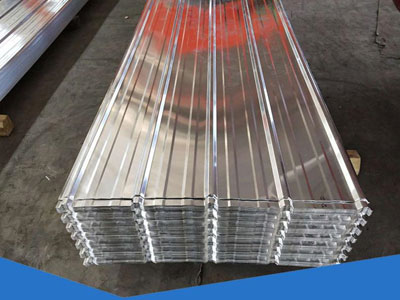

- Aluminum3003 sheet is often used in sheet metal processing of average strength. Formed building panels (roof and siding), food and chemical processing equipment.

- Construction Industry: Roofing, folding panels, siding, garage doors, signage, exterior trim and roofing.

- Oil and Gas: Gasoline or Lube Conduit, Pipe Jacket, Natural Gas Pipelines, etc.

- Chemical and food industry: Food and chemical product handling and storage units, tanks. pipes, pressure vessels for transporting liquid products.

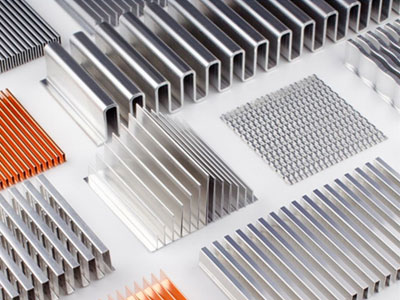

- Heating and cooling equipment: heat exchangers, air conditioner evaporators, car radiators, refrigerator panels

- Household appliances: cookware, fan blades, baking molds, kitchen equipment.

- Packaging: container, bottle cap.

Physical Properties

3003 aluminum density:2.73 g/cm3 (0.0986 lb/in³)

Elastic Modulus:70 GPa

Fatigue Strength:39-90 MPa

3003 aluminum Tensile Strength(Yield):40-210 MPa

Shear Modulus:26 GPa

Shear Strength:68-130 MPa

3003 Aluminum Equivalent

| Item | China | IOS | Japan | Germany | Russia | USA | UK |

| Standard | GB | IOS | JIS | DIM | FOCT4785-1974 | AA/UNS | BS |

| Grade | 3003 | AlMn1Cu | A3003 | AlMnCu/3.0517 | AMu/1400 | 3003/A93003 | 3103(N3) |

3003 Aluminum Cost

The price of 3003 aluminum alloy depends on the cost of 3003 aluminum per kilogram. Including the size of 3003 aluminum alloy, the processing cost of 3003 aluminum alloy, etc.

Here is a formula for calculating the weight of 3003 aluminum alloy. It allows you to understand your required weight very simply:

Aluminum 3003 weight=3003 aluminum density * length * width * thickness

If you have demand for 3003 aluminum plate or other grades of aluminum alloy products. Welcome to inquire, we will provide you with an accurate quotation according to the weight of the product you need and the total demand.

Get a quote

Have questions or need help? Use the form to reach out and we will be in touch with you as quickly as possible.

3003 aluminum alloy supplier

JC Metal is a 3003 aluminum alloy supplier and manufacturer. We can provide various grades of aluminum sheet, aluminum foil, aluminum coil, aluminum rod and other aluminum alloy products. We can also supply 3003 aluminum alloys in full and custom sizes as well as other grades of aluminum alloys.

If you want to know if 3003 aluminum alloy is suitable for your next project, welcome to consult us

FAQ

- Can Aluminum 3003 be bent?

The addition of Mn to the 3003 aluminum alloy does not reduce its ductility. The 3003 aluminum alloy has medium strength, the best cold workability, and an equal high elongation of 25%. It also determines that the 3003 aluminum alloy is the best Applied to bent aluminum alloys.

Although 3003 aluminum alloy is easily bendable, its acceptable minimum bend radius is affected by many factors. Such as tempering, mandrel function, alloy and cross-sectional measurements. So it is also difficult for us to give general rules about bending radii.

2. Can Aluminum 3003alloy be welded?

The weldability of 3003 aluminum is very good. It can be welded by common methods, including gas welding, electric welding and resistance welding. At the same time it can also be welded and brazed by other methods.

Because 3003 aluminum plate has good weldability, it is used in the welding of ships, vehicles and aircraft.

3. Can 3003 aluminum be anodized?

One of its advantages is that aluminum can be anodized. Anodizing can improve the anti-corrosion properties of aluminum, thereby improving the long-term durability of aluminum materials. But, 3003 aluminum alloy is usually avoided for anodizing treatment.

In the process of anodizing, 3003 aluminum alloy is very easy to leave brown color. The color is uneven after anodization, so 3003 aluminum alloy is generally not anodized.

4. Is 3003 aluminum magnetic?

3003 aluminum alloy is not magnetic.