6061 aluminum is the most widely used aluminum alloy in our life. 6061-T6 aluminum is the most commonly used aluminum alloy in 6061 aluminum. What is 6061 T6 aluminum? In this article, the 6061 T6 aluminum alloy will be introduced from the following aspects:

What is 6061-t6 aluminum?

In mechanical design, 6061 T6 aluminum is a commonly used aluminum alloy. Aluminum alloy is an alloy with metal properties by adding one or two main alloying elements on the basis of aluminum. In most aluminum alloys, the aluminum content is 90% to 96%. Major other alloying elements include copper, zinc, manganese, magnesium, silicon, etc.

Aluminum alloys are represented by a four-digit code. The first number identifies the main alloying element of the aluminum alloy. For example, 2XXX includes copper, 4XXX includes silicon, and 6XXX includes magnesium and silicon. The last two digits represent the specific alloy. In 6061, it means that it contains 1% magnesium and 0.4-0.8% silicon and a small amount of other metal elements. So, 6061 aluminum mainly contains aluminum, magnesium and silicon. And aluminum alloys containing small amounts of other elements.

Next, what does 6061 t6 aluminum mean?

No way of naming aluminum alloys just by numbers is complete. There must be a letter and several numbers after the 4-digit code. The letters and numbers show how we treat it. Such as tempering, hardening, and so on. The final properties of aluminum alloys depend to a large extent on the final treatment method. The 6061-T6 aluminum alloy here, T6 means that it has undergone solution heat treatment and artificial aging treatment.

What are the 6061 T6 Aluminum properties / Data Sheet?

First, take a look at the elemental composition of the 6061 T6 aluminum.

| Si | Cu | Mg | Zn | Mn | Ti | Fe | Cr |

| 0.4-0.8 | 0.15-0.4 | 0.8-1.2 | 0.25-0.5 | 0.15-0.5 | 0.15-0.63 | 0.7-0.13 | 0.04-0.35 |

The proportion of Mg and Si in the composition is relatively large. It can be seen that the corrosion resistance and hardness of 6061-T6 aluminum are very good. The hardness of 6061-T6 aluminum can reach HV95 degrees or more.

6061-T6 physical properties

| Melting Onset | 1080 °F (580 °C) |

| Thermal Conductivity | 170 W/m-K |

| Thermal Expansion | 24 μm/m-K |

| Specific Heat Capacity | 900 J/kg-K |

| Electrical Conductivity | 43% IACS (equal volume), 140% (equal weight) |

| Calomel Potential | -740 mV |

| Density | 2.7 g/cm3 |

| Embodied Energy | 150 MJ/kg |

| Ultimate Resilience | 30 MJ/m3 |

| Modulus of Resilience | 520 kJ/m3 |

| Stiffness to Weight | 14 (axial), 50 (bending) |

| Strength to Weight | 31 (axial), 37 (bending) |

| Thermal Diffusivity | 68 m2/s |

| Thermal Shock Resistance | 14 |

6061-T6 aluminum also has the characteristics of 6XXX series aluminum. Such as solderability and good oxidation effect.

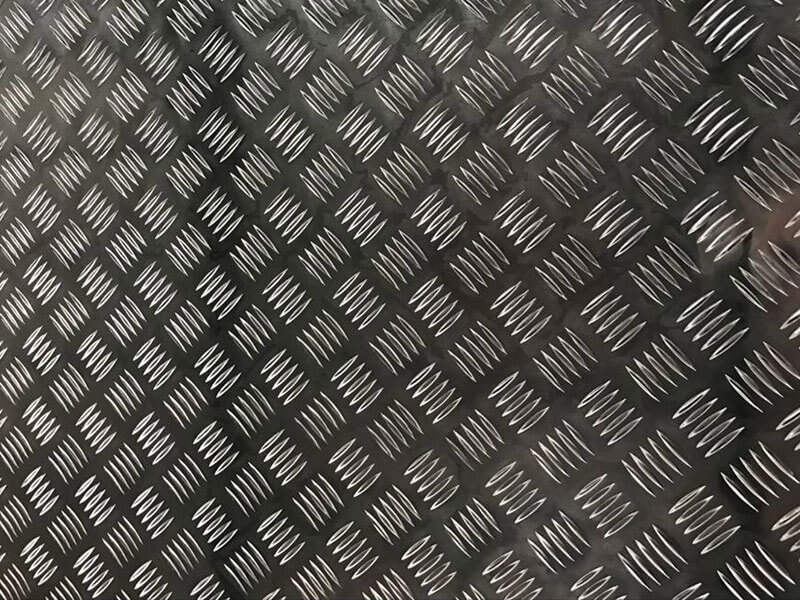

The 6061-T6 aluminum sheet is a hardened aluminum sheet. It can improve the performance and strength of aluminum sheets through rolling, quenching, sawing, and other processes.

The best-selling products are 6061-t6 aluminum coil, 6061-t6 aluminum sheet, bending 6061 t6 aluminum sheet.

According to customer requirements, We can process them into different specifications through different processes. Then use them in different places.

What is the difference between 6061 and 6061 t6 aluminum?

6061 aluminum and 6061-T6 aluminum are mainly reflected in the state and characteristics of the alloy.

6061 aluminum is suitable after heat treatment. A stable product with (or without) work hardening. It is also suitable for products with special requirements for work hardening and heat treatment conditions during the forming process.

- 6061-h32 aluminum sheet

- 6061-o aluminum sheet

- 6061-t0 aluminum sheet

- 6061-t4 aluminum sheet

- 6061-t5 aluminum sheet

- 6061t6 aluminum sheet

The mechanical properties of 6061 aluminum products are not specified. Suitable for products with increased strength through work hardening. After work hardening, the product may be subjected to an extra heat treatment that reduces the strength. Generally, it is a non-heat-treated reinforced material.

The 6061-t6 aluminum is artificially aged after solution heat treatment. It is suitable for products that are no longer cold-worked after solution heat treatment. Can be straightened and leveled. But it does not affect the limit of mechanical properties.

What is 6061-t6 aluminum used for?

6061-T6 aluminum is strong and lightweight. It is the material of choice for the manufacture of ships and some large yachts. Small flat-bottomed canoes made almost entirely of 6061-T6.

6061-T6 aluminum has very good thermal conductivity and heat dissipation performance. It can also be used in air coolers, radiators, heat exchangers, and other equipment that requires heat dissipation.

The non-corrosive nature of 6061-T6 is also used in many fields. Such as air and hydraulic pipes, oil pipes, etc.

Besides, 6061-6T also has many common applications in life. Examples include radios, remote control items, fly fishing reels, bicycle frames, and fire rescue ladders.

Related Products

This paper mainly introduces the properties and applications of 6061 T6 aluminum. For other specific content, please refer to our 6061 product series. At the same time, we also have different types of aluminum sheets, aluminum coils, aluminum foils, and other products for you to choose from. If you have any needs for aluminum products, please feel free to contact us.