Description

20Cr is a low hardenability carburized steel. Most of them are used to manufacture carburized parts with high core strength requirements. The surface of the parts is subject to wear and the section is below 30mm. The shape is complex and the load is not large.

20Cr Worldwide equivalents

| country / region | China | USA | Germany | Japan | Inter |

| Standard | GB | AISI SAE/ ASTM | DIN | JIS | ISO |

| Grade | 20Cr | 5120 | -20Cr4 | ScR420 | 20Cr3 |

Chemical Composition

| C | Si | Mn | P | S | Cr |

| 0.18-0.24 | 0.17-0.37 | 0.50-0.80 | ≤0.030 | ≤0.030 | 0.70-1.10 |

20Cr Steel Mechanical Properties

Tensile strength: ≥835 N/mm2

Yield strength: ≥540 N/mm2

Elongation after break: ≥10%

Rate of reduction in area: ≥40%

Impact absorbing energy: ≥47 J

Material Brinell hardness: ≤179 (annealing or high temperature tempering state)

Test sample size: 15mm

Heat treatment:

First quenching heating temperature: 880 °C ,Cooling: oil or water

Second quenching heating temperature: 780-820 °C ,Cooling: oil or water

Tempering heating temperature: 200 °C,Cooling: water or air

Features

It has good comprehensive mechanical properties after quenching and low-temperature tempering. Good low-temperature impact toughness. Temper brittleness is not obvious.

20Cr steel has good weldability. Generally does not need heat treatment after welding. But parts with a thickness greater than 15mm need to be preheated to 100-150 °C before welding. Tempering heat treatment may not be performed after welding.

20Cr steel has higher strength and hardenability. But the toughness is poor. Under the condition of high temperature normalizing or quenching and tempering, the machinability is good. But the machinability after annealing is poor.

20Cr Steel Application

1. For parts with small heat treatment deformation and high wear resistance. After carburizing, high-frequency surface quenching should be performed. Such as gears, shafts, and spline shafts with a modulus less than 3.

2. This steel can also be used in a quenched and tempered state. It is used to manufacture parts that work at high speeds and withstand moderate impact loads. This steel can also be used as a low-carbon martensitic quenching steel. Further, increase the yield of the steel strength and tensile strength.

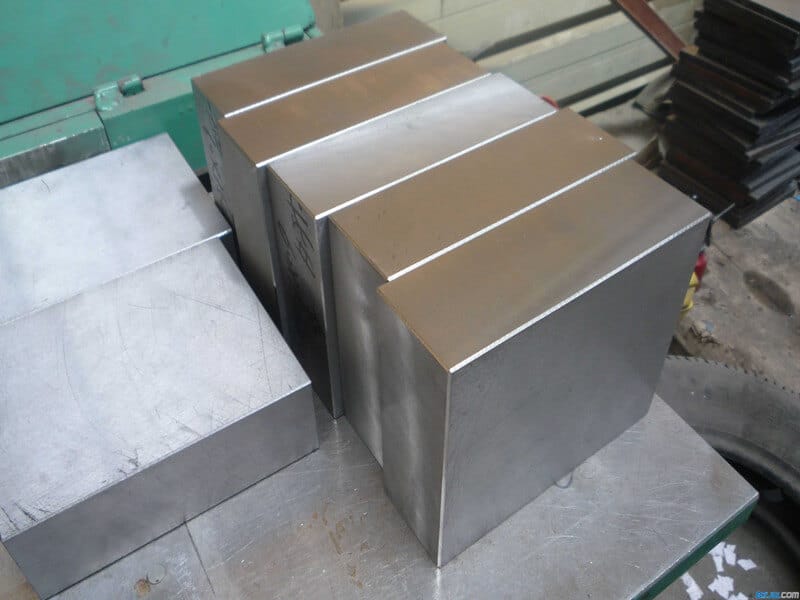

Available Size

| Round Bar | Diameter(mm): 6-800mm ,Length: 1000-9000mm or custom size |

| Plate/Flat/Block | Thickness: 6mm-500mm , Width: 20mm-1000mm or custom size |

| Tolerance | ±1%,Thickness: +/-0.02mm, Width:+/-2mm |