Description

2Cr13(20Cr13 New Grade)

2Cr13 steel is a more commonly used stainless steel, which has high thermal strength, oxidation resistance and good shock absorption. It has good corrosion resistance in weakly corrosive media and has sufficient corrosion resistance to freshwater, seawater, steam, and air. Higher performance can be obtained after heat treatment.

20Cr13 Worldwide equivalents

| – | China | USA | Germany | Japan | France | England | Inter |

| Standard | GB | – | DIN | JIS | AFNOR | BS | ISO |

| Grade | 2Cr13/20Cr13 | 420(S42010) | X20Cr13 (1.4021) | SUS 420J1 | Z20C13 | 420S37 | X20Cr13 |

2Cr13 Steel Material Chemical Composition

| C | Si (≤) | Mn (≤) | P (≤) | S (≤) | Cr | Ni (≤) |

| 0.16 – 0.25 | 1 | 1 | 0.04 | 0.03 | 12.00 – 14.00 | (0.6) |

Mechanical Properties

Tensile strength: 640 N/mm2

Conditional yield strength (Non-proportional extension strength): ≥440 N/mm2

Elongation: ≥20%

Rate of reduction in area: ≥50%

Impact energy: ≥63 Aku2 (J)

Material hardness:

HBW: ≤ 223 (After annealing);

HBW: ≥ 192 (After quenching and tempering)

Physical Properties

Density (g/cm3): 7.75

Melting point: 1470-1510℃

Specific heat capacity (J/Kg·K): 460 at 0-100℃

Electrical Resistivity (μΩ·m): 0.55 at 20℃

Longitudinal modulus of elasticity (kN/mm2): 200 at 20℃

Thermal conductivity:

| Temperature/℃ | 100 | 200 |

| Thermal conductivity (W/m·K) | 22.2 | 26.4 |

Coefficients of linear thermal expansion:

| Temperature/℃ | 0-100 | 0-500 |

| Coefficients of linear thermal expansion (10-6/K) | 10.3 | 12.2 |

Heat treatment

1) Annealing, slow cooling at 800 ~ 900 ℃ or rapid cooling at about 750 ℃;

2) Quenching, 920 ~ 980 ℃ oil cooling;

3) Tempering, rapid cooling at 600 ~ 750 ℃.

Application

2Cr13 stainless steel has high hardness and good corrosion resistance in quenched state. Many of them are used as cutting tools. They are “cutting tool grade” martensitic steel. They are also used as surgical cutting tools. They are similar to the earliest stainless steel such as Brinell high chromium steel. In addition, they are also used as steam turbine blades.

It can also be used to manufacture mechanical parts working below 450 ° C and chemical and food industrial containers used at room temperature.. For example, transmission parts, fixed pins, tie rods, turbine blades, valve seats, valve plates, valve stems, pump parts, molds, etc. Among them, transmission parts, fixed pins, tie rods and other parts are generally used after quenching and tempering.

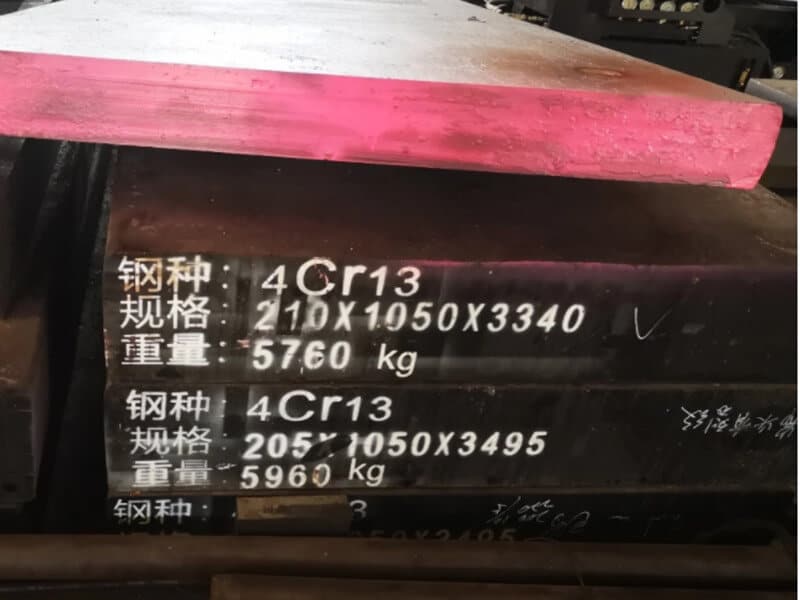

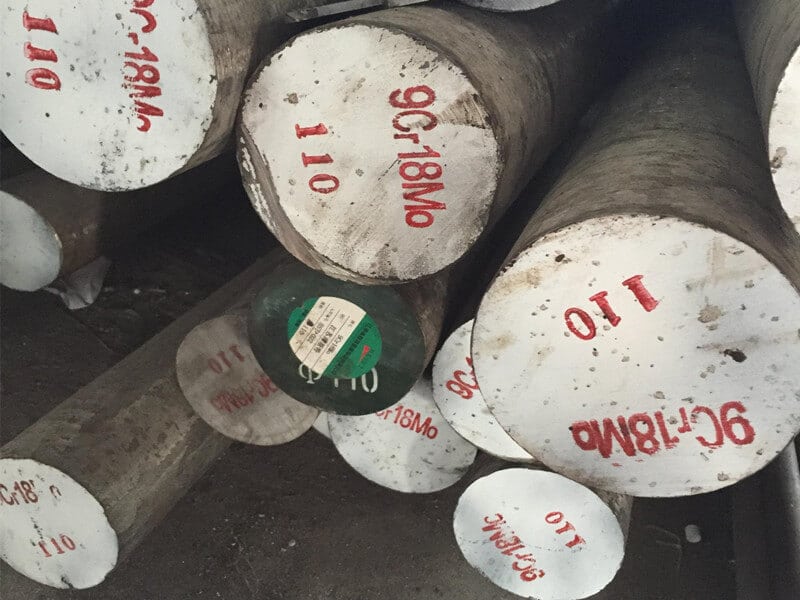

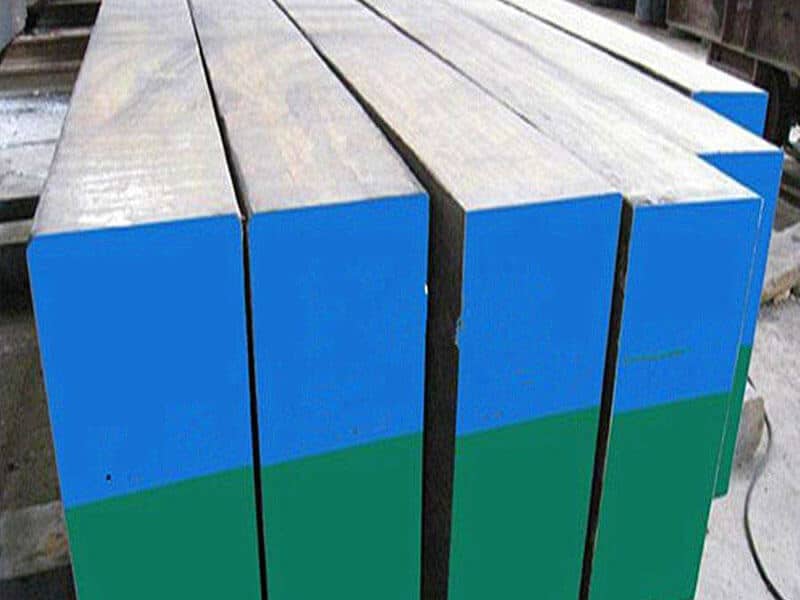

Delivery States

| Product type | Products | Dimension | Processes | Delivery States |

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |