Description

3Cr2W8V is a hot work mold steel. It is a commonly used die-casting mold steel. It has high strength and hardness, good resistance to cold and heat fatigue, good hardenability. But its toughness and plasticity are poor.

It is suitable for making punches and dies that are not subject to impact load under high temperature and high stress. Such as die-casting molds, hot extrusion molds, precision forging dies, and non-ferrous metal forming dies.

3Cr2W8V Steel Worldwide Equivalents

| / | China | USA | Germany | Japan | Ftance | England |

| Standard | GB | DIN,WNr | JIS | AFNOR | BS | |

| Grade | 3Cr2W8V | H21 | X30WCrV9-3 | SKD5 | Z30WCV9 | B3Cr2W8V |

| / | Italy | Poland | Czechia | Russia | Austria | Inter |

| Standard | UNI | PN | CSN | gost | ONORM | ISO |

| Grade | X30WCrV9-3KU | WWW | 19721 | 3KH2V8F | W100 | X30WCrV9-3 |

3Cr2W8V Steel Chemical Composition(%)

| C | V | Si | Mn | P | S | Cr | W |

| 0.3-0.4 | 0.2-0.5 | ≦0.4 | ≦0.4 | ≦0.03 | ≦0.03 | 2.2-2.7 | 7.5-9.0 |

3Cr2W8V Steel Mechanical Properties

| Proof strength Rp0.2(MPa) | Tensile strength Rm(MPa) | Impact energy KV(J) | Elongation at fracture A(%) | Reduction in cross section on fracture Z(%) | As-Heat-Treated Condition | Brinell hardness(HBW) | Proof strength Rp0.2(MPa) |

| 139(≥) | 865(≥) | 12 | 24 | 44 | Solution and Aging, Annealing, Ausaging,Q+T | 411 | 139(≥) |

3Cr2W8V Steel Physical properties

| Property | Density kg/dm3 | Temperature T °C/F | Specific heat J/kgK | Thermal conductivity W/mK |

| 716(≥) | 143(≥) | 34 | 43 | 41 |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0)N/mm2 | Creep rupture strength (10000h) (Rp1,0)N/mm2 | Electric resistance µΩ·cm | Modulus of elasticity kN/mm2 |

| 614 | 871 | 395 | Solution and Aging,Annealing, Ausaging,Q+T | 432 |

Heat Treatment

Forging

Heat to 900-1100 °C(1652-2012°F),forged temperature not below 843℃(1550°F)

Annealing

Slowly heated to 800~850 ºC(1472~1562°F) and allow enough times, let the steel to be thoroughly heated, Then cool slowly at Maximum of 4°C(40°F)per hours. The 3Cr2W8V tool steel will get MAX 235 HB (Brinell hardness).

Hardening

3Cr2W8V steels should be heated uniformly to 1050-1100°C (1922-2012°F) until completely heated through. If needed, the steels can be preheated at 300-500°C (572-932°F). About 30 min/per 25 mm of ruling section is to be provided and then the steels should be immediately quenched in air.

Tempering

Tempering of 3Cr2W8V steels is performed at 600-650°C (212-662°F), Soak well at the selected temperature and soak for at least one hour per 25mm of total thickness. Get Rockwell C hardness of 50 MAX..

Application

3Cr2W8V hot work mold steel is especially suitable for hot forging and blanking dies and punches. Used to make nuts, bolts, and other similar small parts. Dies, cores, inserts, pins, etc. for copper-based alloy die-casting. Other uses include forming dies, shear blades, hot extrusion dies, mandrels, punches, die sets, ejector discs.

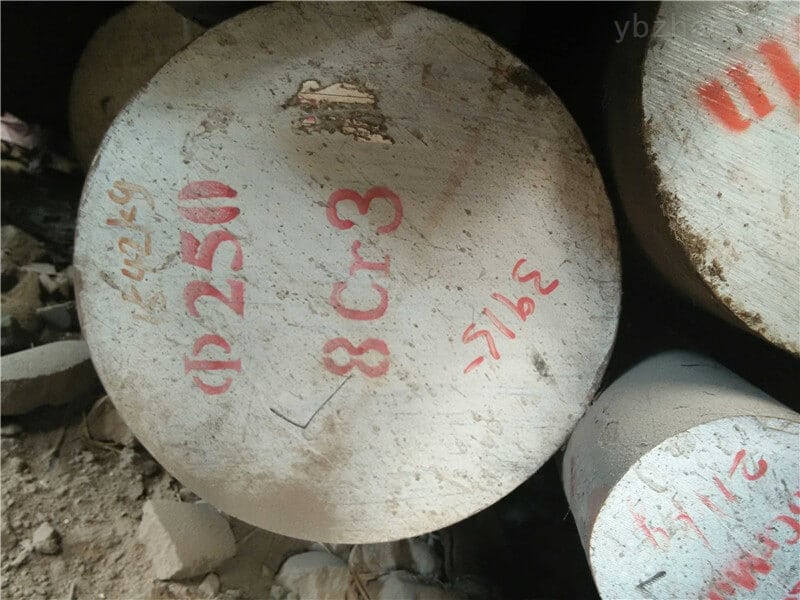

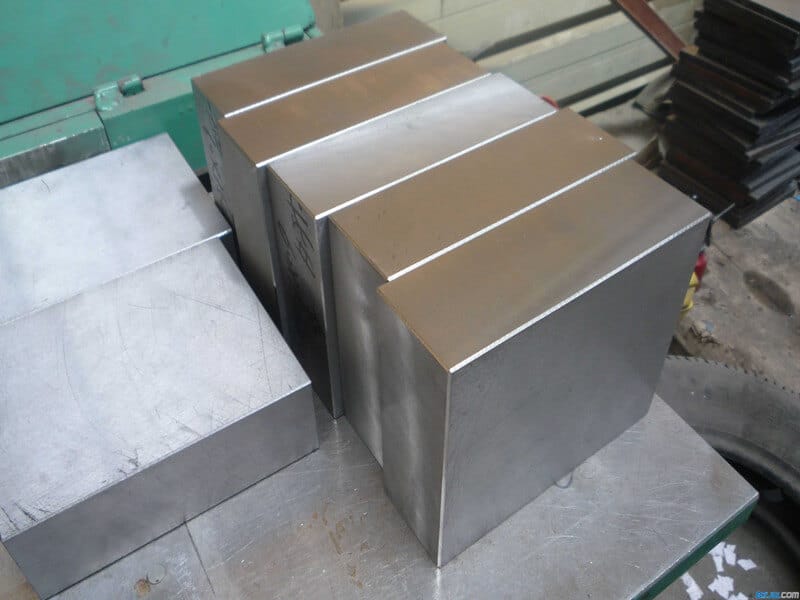

3Cr2W8V products

| Product type | Products | Dimension | Processes | Delivery States |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |