Description

40Cr steel is one of the most widely used steels in machinery manufacturing. After quenching and tempering treatment, it has good comprehensive mechanical properties. Good low-temperature impact toughness and low notch sensitivity. Besides to quenching and tempering treatment, it is also suitable for cyanidation and high-frequency quenching treatment. Good cutting performance. When the hardness is 174~ At 229HB, the relative machinability is 60%.

40Cr steel Worldwide equivalents

| China | Japan | France | England |

| GB | JIS | AFNOR | BS |

| 40Cr | SCr440 | 42C4 | 530A40 / 530M40 |

| USA | Germany | ISO | Sweden |

| ASTM/AISI/UNS/SAE | DIN, WNr | ISO | SS |

| 5140 / G51400 | 41Cr4 / 1.7035 | 41Cr4 | 2245 |

40Cr Steel Chemical Composition

| C(%) | Si(%) | Mn(%) | Cr(%) | P(%) | S(%) | Cu(%) | Ni(%) | Mo |

| 0.37-0.44 | 0.17-0.37 | 0.50-0.80 | 0.80-1.10 | MAX 0.035 | MAX 0.035 | MAX 0.30 | MAX 0.30 | MAX 0.15 |

40Cr Steel Mechanical Properties

- Yield Point: ≥ 785 MPa

- Impact Absorbing Energy: ≥ 47 J

- Tensile Strength: ≥ 810 MPa

40Cr steel Physical Properties

| Property | Density kg/dm3 | Temperature T °C/F | Specific heat J/kgK | Thermal conductivity W/mK |

| 228(≥) | 348(≥) | 11 | 14 | 32 |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0)N/mm2 | Creep rupture strength (10000h) (Rp1,0)N/mm2 | Electric resistance µΩ·cm | Modulus of elasticity kN/mm2 |

| 233 | 354 | 659 | Solution and Aging, Annealing, Ausaging,Q+T, etc | 332 |

Heat treatment

Annealing of 40Cr steel

Slowly heated to 850 ℃ and allow enough times, let the steel to be thoroughly heated, Then cool slowly in the furnace. The 40CR alloy steel will get MAX 250 HB (Brinell hardness).

Hardening of 40Cr steel

Heated slowly to 880-920°C, Then after adequate soaking at this temperature quench in oil. Temper as soon as tools reach room temperature.

40Cr Steel Application

1. After quenching and tempering at medium temperature, it is used to manufacture parts that are subjected to high load, impact and medium speed work. Such as gears, spindles, oil pump rotors, sliders, and collars.

2. After quenching and low temperature tempering, it is used to manufacture parts with heavy load, low impact and wear resistance, and the solid thickness on the section is below 25mm. Such as worm, spindle, shaft, collar.

3. After quenching and tempering and high-frequency surface quenching, it is used to manufacture parts with high surface hardness and wear resistance without great impact. Such as gears, sleeves, shafts, main shafts, crankshafts, mandrels, pins, Connecting rods, screws, nuts, intake valves.

4. It is suitable for the manufacture of various transmission parts for carbonitriding treatment, such as gears and shafts with large diameters and good low-temperature toughness.

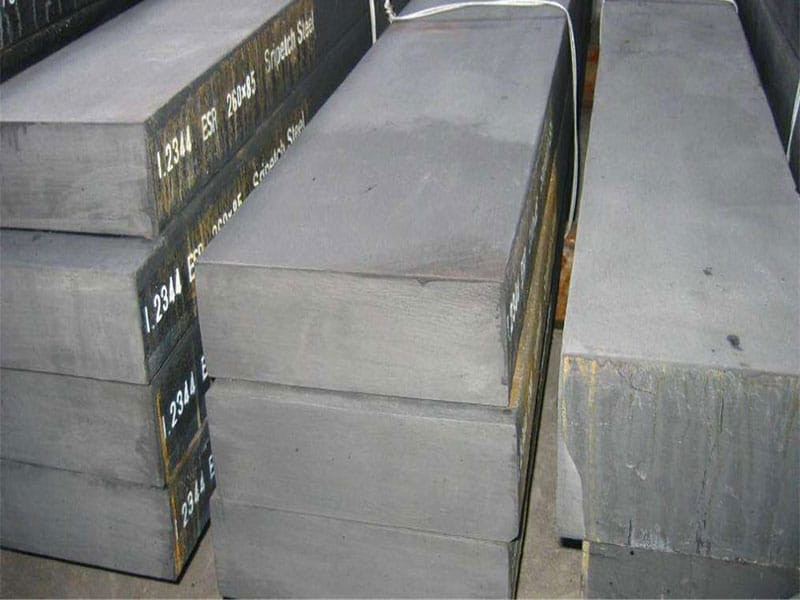

40Cr Products

| Product type | Products | Dimension | Processes | Delivery Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging,Q+T, ACID-WASHED,Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling, and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging,Q+T, ACID-WASHED,Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging,Q+T, ACID-WASHED |