Description

4CrMnSiMoV steel is one of the steel grades developed in China in the field of low alloy large section hot work die steel in the past 20 years.

4CrMnSiMoV steel has high tempering resistance and good high temperature strength, thermal fatigue resistance and toughness. It also has good hardenability and good cold and hot working properties. The steel is suitable for the manufacture of various types of hammer dies and press forging dies.

4CrMnSiMoV Chemical Composition

| C | Si | Mn | P (≤) | S (≤) | Cr | V |

| 0.35-0.45 | 0.80-1.10 | 0.80-1.10 | 0.030 | 0.030 | 1.30-1.50 | 0.2-0.4 |

4CrMnSiMoV Mechanical Properties

| Proof strength | Tensile strength | Impact energy | Elongation at fracture | Reduction in cross section on fracture | As-Heat-Treated Condition | Brinell hardness(HBW) |

| 313(≥) | 425(≥) | 44 | 44 | 22 | Solution and Aging, Annealing, Ausaging, Q+T | 112 |

Physical Properties

| Property | Density kg/dm3 | Temperature T °C/F | Specific heat J/kgK | Thermal conductivity W/mK |

| 124(≥) | 299(≥) | 33 | 31 | 32 |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0)N/mm2 | Creep rupture strength (10000h) (Rp1,0)N/mm2 | Electric resistance µΩ·cm | Modulus of elasticity kN/mm2 |

| 965 | 627 | 847 | Solution and Aging, Annealing, Ausaging, Q+T | 222 |

Heat Treatment

Hot Working Specifications

Steel ingot: heating temperature 1160~1180℃, starting temperature 1100~1150℃, end temperature ≥850℃, slow cooling (sand cooling or pit cooling).

Steel billet: heating temperature 1100~1150℃, starting temperature 1050~1100℃, end temperature ≥850℃, slow cooling (sand cooling or pit cooling).

Isothermal Annealing Specifications

Annealing temperature is 840~860℃, heat preservation is 2~4h, isothermal temperature is 700~720℃, heat preservation is 4~8h, and the furnace is cooled to below 500℃ for air cooling.

General Quenching Specification

Quenching temperature 860~880℃, oil cooling, hardness 56~58HRC. 4CrMnSiMoV Steel

Application

- 1) 4CrMnSiMoV steel is suitable for large and medium forging dies.

- 2) Compared with the service life of hot die steel such as 5CrNiMo, the service life of this steel is the highest. Such as connecting rod die, front beam die, gear die, flange segment die (deep die), etc., the service life of the 5CrNiMo die is increased by 1 to 0.8 times.

- 3) The service life of straightening dies, bending dies and flat forging dies is generally 0.5 times higher than that of 5CrNiMo. Individuals exceed 1 to 2 times.

- 4) Used to make hammer forging dies, press forging dies and bending dies.

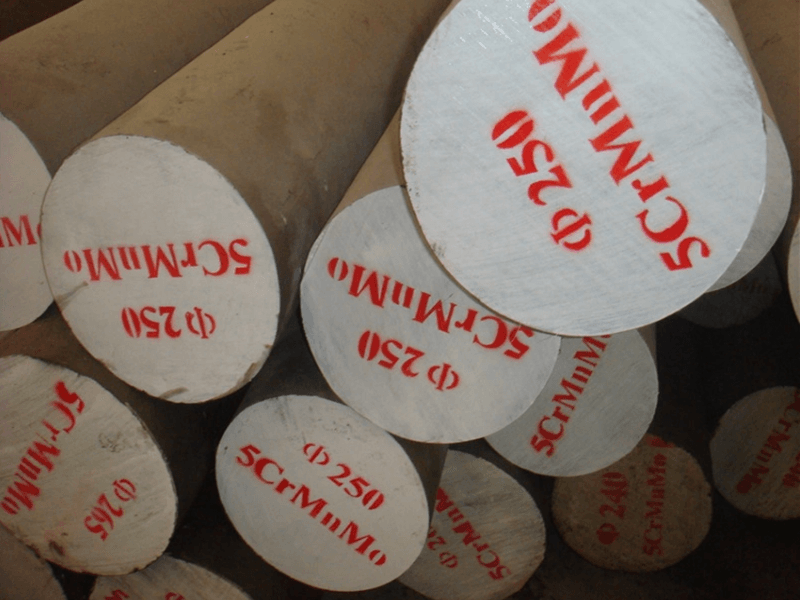

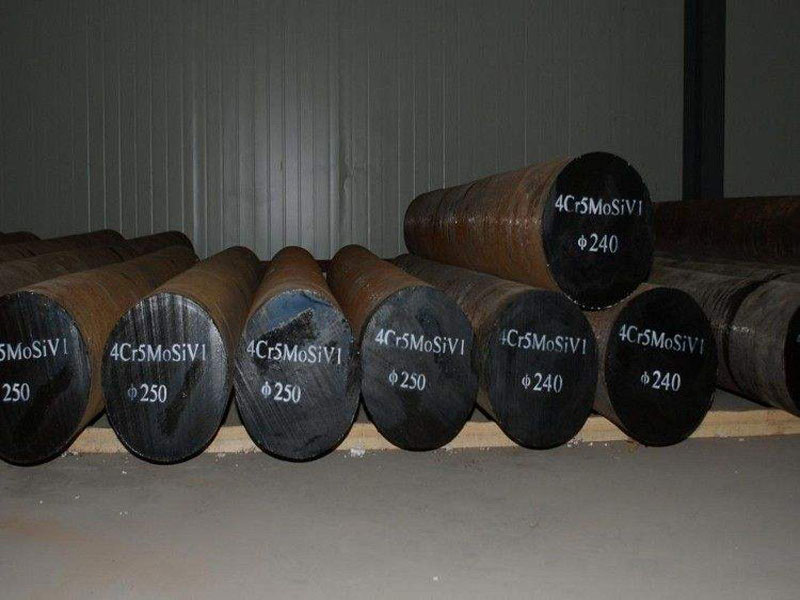

4CrMnSiMoV steel products:

| Product type | Products | Dimension | Processes | Delivery Status |

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |