Description

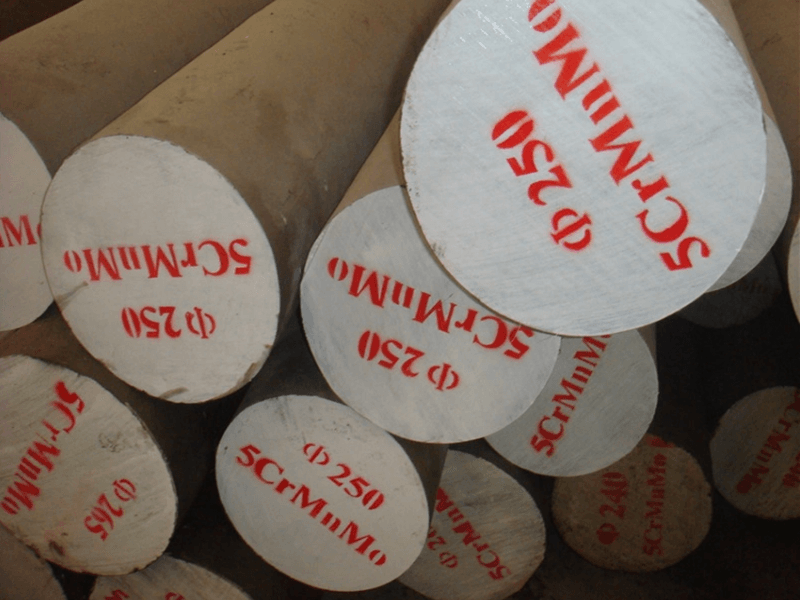

Mold Steel 5CrMnMo is developed on the basis of medium carbon steel by adding three elements of Cr, Mn, Mo. The steel is a hot work die steel with slightly poor hardenability and thermal fatigue resistance.

Steel is suitable for various types of forging dies with high strength and high wear resistance.When higher toughness is required, electro slag remelting steel can be used.

The carbon content in 5CrMnMo steel is kept at 0.40%~0.60%. High strength and thermal fatigue strength can be obtained. Good toughness and thermal conductivity.

5CrMnMo Steel Chemical Composition

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

| 0.50~0.60 | 0.25~0.60 | 1.20~1.60 | ≤0.030 | ≤0.030 | 0.60~0.90 | ≤0.20 | 0.15~0.30 | ≤0.30 |

5CrMnMo Steel Mechanical Properties

| Proof strength Rp0.2(MPa) | Tensile strength Rm(MPa) | Impact energy KV(J) | Elongation at fracture A(%) | Reduction in cross section on fracture Z(%) | As-Heat-Treated Condition | Brinell hardness(HBW) |

| 925(≥) | 381(≥) | 11 | 11 | 32 | Solution and Aging, Annealing, Ausaging, Q+T, | 123 |

5CrMnMo Steel Physical Properties

| Property | Density kg/dm3 | Temperature T °C/F | Specific heat J/kgK | Thermal conductivity W/mK |

| 756(≥) | 372(≥) | 33 | 43 | 12 |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0)N/mm2 | Creep rupture strength (10000h) (Rp1,0)N/mm2 | Electric resistance µΩ·cm | Modulus of elasticity kN/mm2 |

| 881 | 267 | 836 | Solution and Aging, Annealing, Ausaging, Q+T | 331 |

Heat Treatment

Stress relief before quenching

Annealing: heat at 760-780℃ and keep it for 150 min, cool to 500℃, and then air-cool.

Quenching

After heating and holding at 650°C for 80 minutes, heat and hold at 850°C for 150 minutes to oil cooling (oil temperature around 40°C) to room temperature.

Tempering-Use three temperings

- For the first time, heat and hold at 500℃ for 3h, and cool to room temperature in air.

- For the second time, heat and keep at 450℃ for 4h, and cool to room temperature in air.

- For the third time, heat and keep at 300℃ for 5h to cool to room temperature.

- In this way, the hardness can reach about HRC43, which has good edge crack resistance and prolongs the service life of the mold.

Features and Application

Steel is suitable for various types of forging dies with high strength and high wear resistance. When higher toughness is required, electro slag remelting steel can be used.

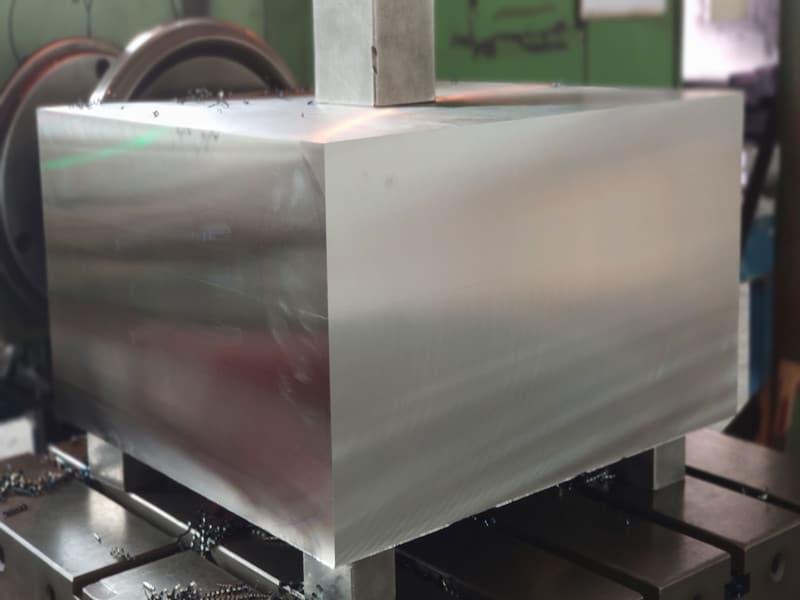

5CrMnMo products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |