Description

5Cr2NiMoVSi steel belongs to a large section of hot forging work steel. It has high hardenability. When the steel is heated, the growth tendency of austenite grains is small. The heat treatment temperature range is wide. The thermal stability, thermal fatigue performance and impact toughness of the steel are better. Suitable for making presses with large cross-sections, and hot-working molds for mold-forging hammers.

5Cr2NiMoVSi Steel Chemical Composition

| C | Si | Mn | Cr | Ni | Mo | V | P | S |

| 0.40~0.53 | 0.60~0.90 | 0.4~0.6 | 1.54~2.00 | 0.80~1.20 | 0.80~1.20 | 0.30~0.50 | ≤0.030 | ≤0.030 |

5Cr2NiMoVSi Physical properties

| Temperature (°C) | Modulus of elasticity (GPa) | Mean coefficient of thermal expansion 10-6/(°C) between 20(°C) and | Thermal conductivity (W/m·°C) | Specific thermal capacity (J/kg·°C) | Specific electrical resistivity (Ω mm²/m) | Density (kg/dm³) | Poisson’s coefficient, ν |

| 21 | – | – | 0.14 | – | |||

| 745 | 185 | – | 22.3 | 243 | – | ||

| 398 | – | 42 | 33.2 | 213 | 424 |

Heat Treatment

Preheat at 650°C and quench at 985°C. 2 tempering.

1–Preheat at 650℃. The purpose is to reduce thermal stress. Prevent deformation and cracking.Increasing the quenching temperature will further increase the tempering stability of the steel.Considering that the increase of the quenching temperature will have an adverse effect on the plasticity and toughness. We use 985℃ quenching.2–The first tempering is based on the design hardness of the mold. Select the tempering temperature according to the tempering curve of the material. The purpose is to make it reach the hardness required for use.

3–The second tempering temperature is 20~40℃ lower than the first one. In this way, the martensite transformed from retained austenite during the first tempering cooling process can also be tempered.

5Cr2NiMoVSi Features and Application

1–Good hardenability. It ensures the toughness of the mold base.

This steel has high alloying element content. Each main element can improve the hardenability. So the steel has good hardenability. The strength of the matrix after heat treatment of the mold is guaranteed.

2–Good tempering resistance. Improve the high-temperature performance of the mold.

Due to the high quenching temperature of this steel, the solid solubility of alloying elements in the matrix is increased. Each alloying element can enhance or promote the secondary hardening of the steel. Improves the tempering resistance of steel. Improved tempering resistance means better thermal stability. The mold can still maintain high strength and hardness at high temperatures. The deformation resistance of the mold is improved. In this way, the collapse of the mold and the deformation of the cavity is greatly reduced.

3–Good antioxidant properties.

The Cr content of the steel is relatively high, and S is added. Antioxidant properties are significantly improved. When forging to 4300 pieces, the groove of the mold is still brighter. Reduced friction coefficient. Reduce mold wear

5Cr2NMoVSi steel is often used in the manufacture of forging mold on various presses. Hammer forging mold. The 5Cr2NiMoVSi average service life of high dry 5CrNiMo steel is about 5 times

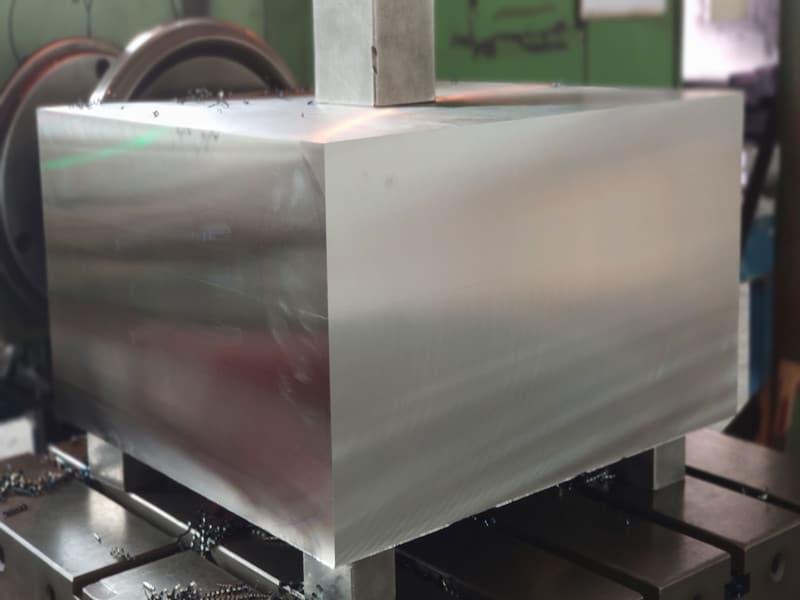

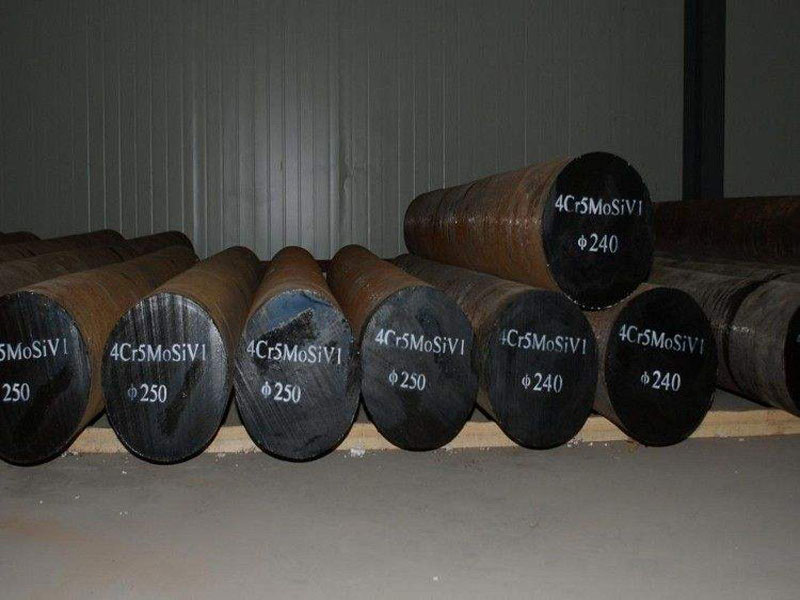

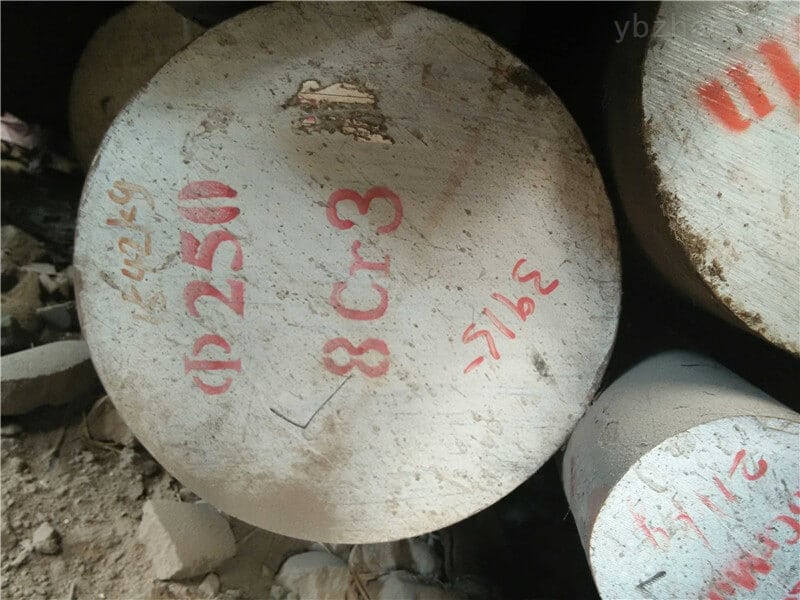

5Cr2NiMoVSi products

| Product type | Products | Dimension | Processes | Delivery Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |