Description

5CrNiMoV is a high wear resistance hot forging mold steel. Good toughness, high strength and good wear resistance. The mold steel produced by electric arc furnace (EAF) + refining (LT) + vacuum (VD) has high purity and good performance.

5CrNiMoV Chemical Composition

| C | Si | Mn | P | S | Cr | Mo | Ni | V |

| 0.5~0.6 | ≤0.35 | 0.5~0.8 | ≤0.03 | ≤0.03 | 0.8~1.1 | 0.35~0.5 | 1.4~1.8 | 0.1~0.3 |

Heat Treatment

Annealing: 760-780℃ Hardness: 197-241HB

Quenching temperature: 890-910℃, oil cooling, hardness: 61.5HRC

Tempering temperature: 420-550℃, tempering twice

Hardness: 38-47HRC

This steel can be hardened when cooled in the air, and is easy to form white spots, so it should be cooled slowly after forging.

For large forgings, it must be placed in a furnace at 600°C, and after the temperature is consistent, slowly cooled to 150-200°C, and then cooled in air.

For larger forgings, it is recommended to immediately perform tempering and heating after cooling to 150-200°C.

Features and Application

Generally used to make various large and medium forging dies.

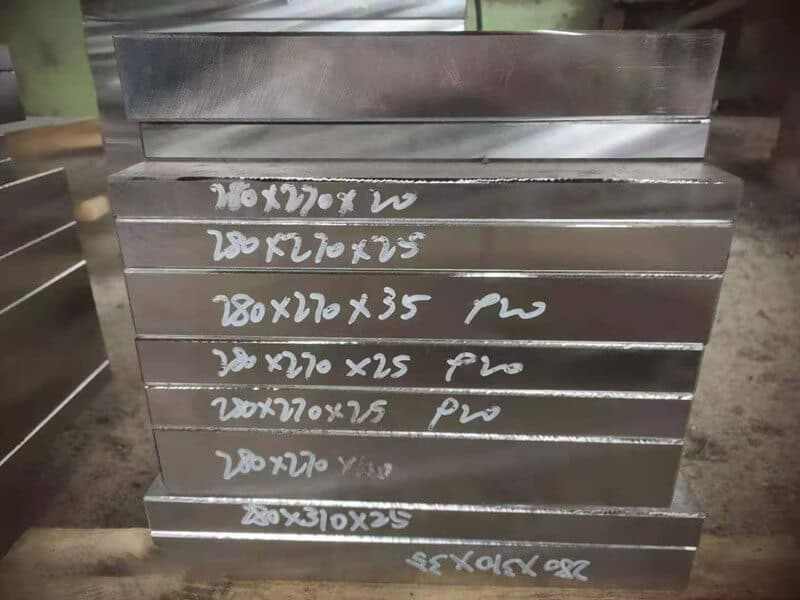

5CrNiMoV products

| Product type | Products | Dimension | Processes | Delivery Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |