Description

6Cr4Mo3Ni2WV steel is a new type of die steel of the base steel type. The steel has high strength, good red hardness and good toughness.

6Cr4Mo3Ni2WV Chemical Composition)

| C | Mn | Si | Cr | Mo | W | V | Ni | P | S |

| 0.55~0.64 | ≤0.04 | ≤0.04 | 3.80~4.40 | 2.8~3.3 | 0.9~1.3 | 0.9~1.3 | 1.8~2.2 | ≤0.03 | ≤0.03 |

6Cr4Mo3Ni2WV Physical Properties

Critical temperature of 6Cr4Mo3Ni2WV steel

| Critical point | Ac1 | Ac3 | Ar1 | Ms |

| Temperature (approximate) / ℃ | 737 | 822 | 650 | 180 |

Mass constant pressure heat capacity of 6Cr4Mo3Ni2WV steel

| Temperature / ℃ | 20 | 200 | 400 | 500 | 600 | 700 |

| Mass constant pressure heat capacity CP / J · (kg · K) | 572.6 | 585.2 | 652.0 | 710.6 | 794.2 | 948.8 |

Linear expansion coefficient of 6Cr4Mo3Ni2WV steel

| Temperature / ℃ | 18~100 | 18~200 | 18~300 | 18~400 | 18~500 | 18~600 | 18~700 |

| Linear expansion coefficient / ℃ | 11.1×10 | 11.2×10 | 11.9×10 | 12.5×10 | 12.3×10 | 13.1×10 | 13.3×10 |

Thermal conductivity of 6Cr4Mo3Ni2WV steel

| Temperature / ℃ | 20 | 200 | 400 | 500 | 600 | 700 |

| Thermal conductivity λ/ W·(m·K) | 34.3 | 33.4 | 32.6 | 32.2 | 31.8 | 31.4 |

Elastic modulus of 6Cr4Mo3Ni2WV steel

| Temperature / ℃ | 20 | 200 | 300 | 600 | 650 |

| Elastic modulus E / MPa | 200000~218000 | 185000~200000 | 187000~195000 | 160000~168000 | 156000~161000 |

Features and Application

- The steel has a wide heat treatment temperature range. Basically no quenching cracking phenomenon. According to the conditions of the mold, the heat treatment process can be adjusted appropriately.

- For cold work molds, tempered at 520~560℃ can be selected

- For hot work molds, tempering at 600~650℃ can be selected.

This steel can be used to manufacture hot extrusion bearing ring punch, hot extrusion die, hot stamping die, precision forging die. In addition, it can also be used as cold extrusion die, cold heading die.

The hot working process of this steel is difficult to master. The tendency of forging cracking is more serious. Attention should be paid to the hot working.

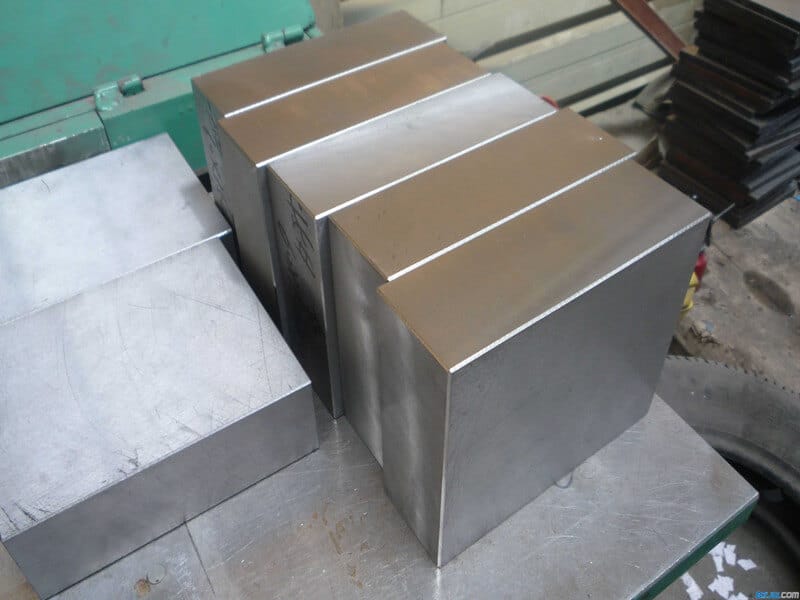

6Cr4Mo3Ni2WV products

| Product type | Products | Dimension | Processes | Delivery Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

Our Services

1. The price is determined according to the material, size, finishing process and different payment methods

2. Each material has been ut tested

3. We have every kind of material in stock, so we can deliver it in time.

4. The size of steel can be customized according to customer requirements, and the minimum order quantity and specification model can be developed / produced according to international, Chinese or industrial standards

5. There are more services. Welcome to consult.