Description

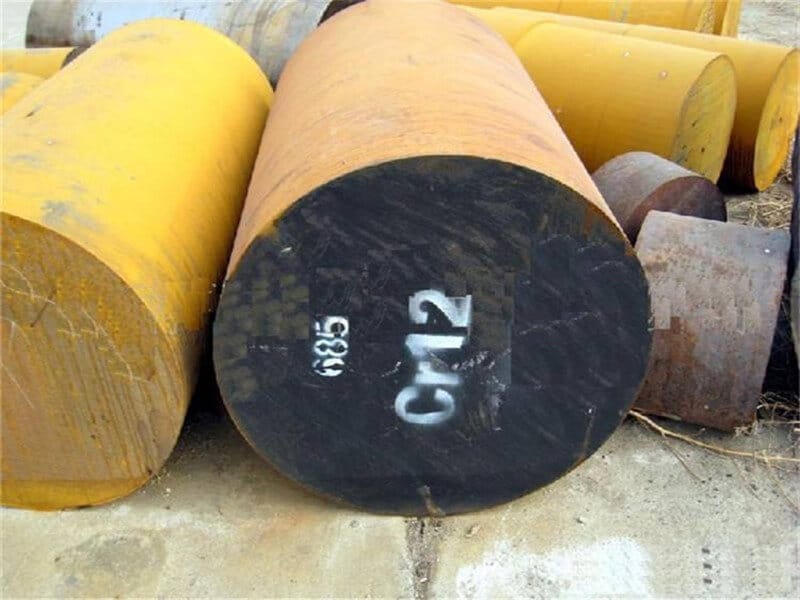

7Cr7Mo3V2Si is a high strength and toughness cold work die steel. Compared with Cr12 type cold work die steel and W6Mo5Cr4V2 high-speed steel, it has higher strength and toughness. Better wear resistance.

7Cr7Mo3V2Si Chemical Composition

| C | Si | Mn(≤) | P (≤) | S (≤) | Cr | V | Mo |

| 0.7-0.8 | 0.7-1.8 | 0.50 | 0.003 | 0.03 | 6.5-7.5 | 1.7-2.2 | 2.0-3.0 |

Heat Treatment

Thermal processing

The heating temperature is 1120-1140℃, the initial forging temperature is 1100-1200℃. The final forging temperature is ≥850℃. The cooling method after forging is sand cooling.

Isothermal annealing

Heating temperature 8500℃±10℃, time 2-3h. Furnace cooling to temperature 740℃±10℃, time 4-6h. Slowly cooling to temperature ≤600℃, air cooling, hardness 210-240HBS.

Quenching/Tempering

Quenching temperature is 1100℃±10℃, after 25s/mm heating and heat preservation, oil cooling quenching.The first tempering temperature is 540℃±10℃, time is 2h, air cooling.The second tempering temperature is 540℃±10℃, the time is 1.5h, and the hardness is 59-62HRC.Quenching temperature 1100-1150℃, oil-cooling quenching. Tempering temperature 550-570℃, time 1-2h, tempering times 2-3 times. Hardness 58-60HRC.

7Cr7Mo3V2Si Steel Application

1. 7Cr7Mo3V2Si is a cold work mold steel. Such as cold extrusion die, blanking die, cold heading die, deep drawing film, bending die.

2. 7Cr7Mo3V2Si can also be used as plastic mold steel.

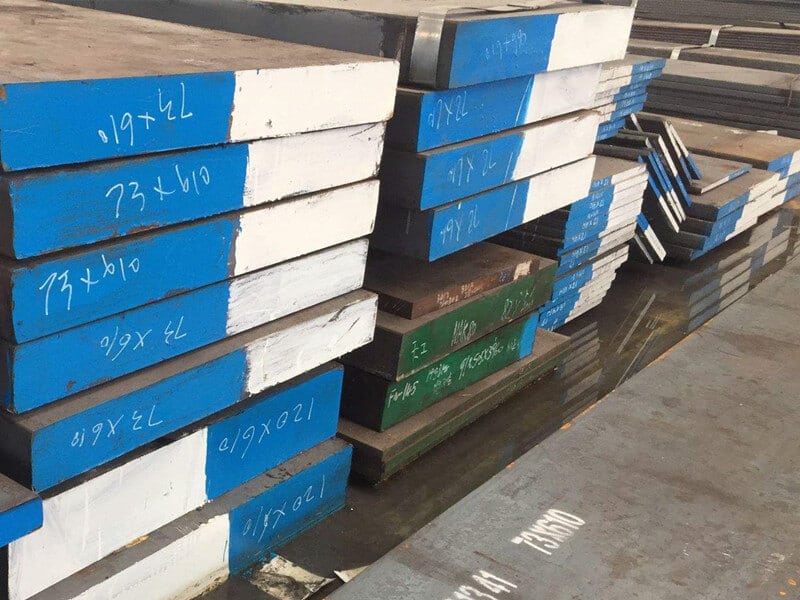

7Cr7Mo3V2Si Products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |