Description

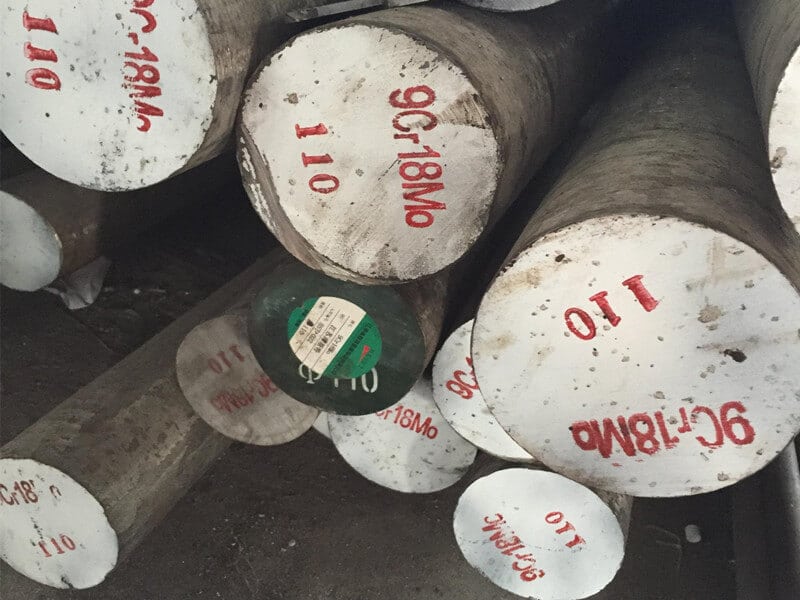

9Cr18 steel is high carbon high chromium martensitic stainless steel. After quenching, it has high hardness, high wear resistance and corrosion resistance. The steel is suitable for manufacturing plastic molds. It can withstand high wear resistance, high load, and corrosive media. The steel belongs to the Leyburst steel body. It is easy to form uneven carbide segregation and affect the service life of the mold. So, the hot processing process must be strictly controlled during hot processing.

It is similar to those of Cr17. 9Cr18 new name is 95Cr18. that is to say, 95Cr18 =9Cr18.

Equivalent Grade

| Country | China | USA | Germany | Japan | France | UK |

| Standard | GB/T 1220 | AISI | DIN EN 10088-3 | JIS G4303 | NF A35-572 | EN 10088-3 |

| Grade | 9Cr18 (95Cr18 | 440C | X105CrMo17 (1.4125) | SUS 440C | Z100CD17 | X105CrMo17 (1.4125) |

Chemical Composition

| Steel Grade | C | Si (≤) | Mn (≤) | P (≤) | S (≤) | Cr | Ni (≤) |

| 9Cr 18,95Cr18 | 0.90-1.00 | 0.8 | 0.8 | 0.04 | 0.03 | 17.00-19.00 | -0.6 |

Mechanical Properties

- Material HRC Hardness: ≥ 55 (Quenching and tempering);

- Material HBW Hardness: ≤ 255 (Annealing)

Physical Properties

- Density (g/cm3): 7.70

- Melting point: 1377-1510

- Specific heat capacity (J/Kg·K): 480 at 0-100℃

- Thermal conductivity (W/m·K): 29.3 at 100℃

- Coefficients of linear thermal expansion (10-6/K):

- 10.5 (0-100℃)

- 12.0 (0-500℃)

- Electrical Resistivity (μΩ·m): 0.60 at 20℃

- Longitudinal modulus of elasticity (kN/mm2): 200 at 20℃.

- Magnetic: Yes

Heat Treatment Specification

- Annealing: 800 – 920 ℃ (Slow cooling)

- Quenching: 1000 – 1050 ℃ (Oil cooling)

- Tempering: 200 – 300 ℃ (Oil or air cooling)

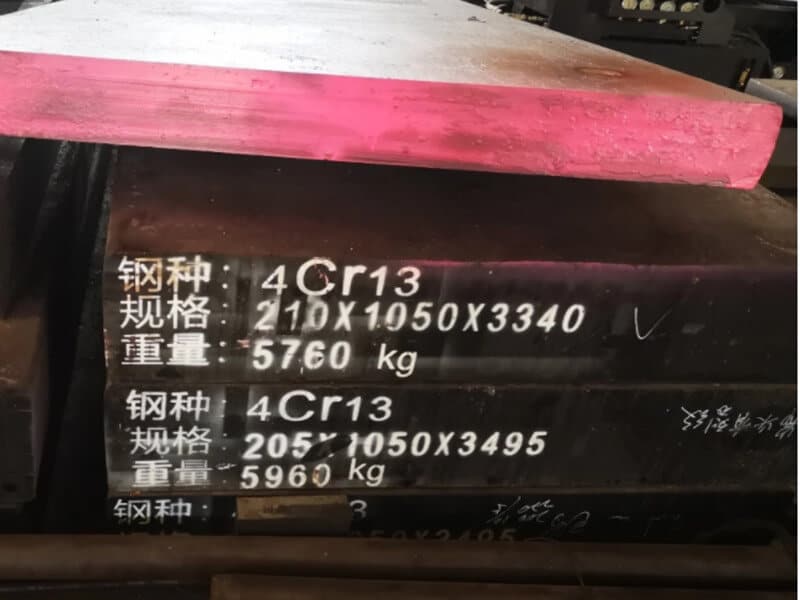

Delivery Condition

The delivery is generally in the heat treatment state. The type of heat treatment is indicated in the contract.

Applications

9Cr18 stainless steel is used for stainless slicing machine cutting tools and cutting tools, surgical blades, high wear-resistant equipment parts, pumps, valve parts, rods, springs, fasteners, etc.