Description

9SiCr steel is low alloy steel for cutting tools. It is also often used to make cold work mold parts. The effect is very good. It has higher hardenability and hardenability than chromium steel (Cr2 or 9Cr2). It has higher tempering stability. Suitable for graded quenching or isothermal quenching. The steel can be used for a variety of cold work mold parts with complex shapes and small deformation requirements.

9SiCr Steel Worldwide Equivalents

| / | China | England | Germany | Sweden |

| Standard | GB | BS | DIN,WNr | SS |

| Grade | Cr12MoV | BL3 | 1.2067 100Cr6 | 2092 |

| / | France | Spain | USA | Russia |

| Standard | AFN0R | UNE | AISI/sAE | roct |

| Grade | Y100C6 | 100Cr6 | L3 | 9XC |

9SiCr Steel Chemical Composition of 9SiCr Steel

| C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | V(%) | Cu(%) |

| 0.85~0.95 | 1.20~1.60 | 0.30~0.60 | ≤0.030 | ≤0.030 | 0.95~1.25 | ≤0.20 | ≤0.20 | ≤0.30 |

9SiCr Steel Mechanical Properties

| Elongation at fracture A(%) | Reduction in cross section on fracture Z(%) | As-Heat-Treated Condition | Brinell hardness(HBW) |

| 22 | 14 | Solution and Aging,Annealing,Ausaging,Q+T,etc | 214 |

| Proof strength Rp0.2(MPa) | Tensile strength Rm(MPa) | Impact energy KV(J) | |

| 518(≥) | 661(≥) | 44 |

9SiCr Steel Physical properties

| Property | Density kg/dm3 | Temperature T °C/F | Creep rupture strength (10000h) (Rp1,0)N/mm2 | Temp. °C/°F |

| 315(≥) | 899(≥) | 23 | 638 | 216 |

| Specific heat J/kgK | Thermal conductivity W/mK | Electric resistance µΩ·cm | Modulus of elasticity kN/mm2 | Creep strain limit (10000h) (Rp1,0)N/mm2 |

| 41 | 14 | Solution and Aging,Annealing,Ausaging,Q+T,etc | 212 | 519 |

Heat Treatment

Thermal processing

It needs to be heated in a neutral atmosphere or protective atmosphere furnace.

- The preheating temperature is 700~80O°C for the first time. Holding time 1. 0 ~1.5h.

- The second time is 850~900°C, and the holding time is 2min/mm. After the heat preservation, the temperature is raised to 1100~1150°C at a heating rate of ≤100°C. The holding time is 1.0~1.5min/mn. Open forging temperature 1050~1100°C. Repeated double cross-direction upsetting forging, the alloy carbide grade after forging is less than or equal to grade 2.

Forging heat quenching and tempering treatment.

Oil quenching at 900°C high-temperature waste heat. Then high-temperature tempering at 700~720°C. The hardness reaches 200~220HBW. It can replace the spheroidizing isothermal annealing after forging.

Normalizing

Normalizing temperature 900 ~920°C. Holding time: Salt bath furnace 25 ~30s/mm, air cooling furnace 70 ~90s/mm, air cooling, hardness 321~415HBW.

Spheroidizing Annealing790~810℃×2~4h, furnace cooling, 700~720℃×3~4h. with a cooling rate of ≤30°C/h, slowly furnace cool to 500~600℃. air cooling, hardness 179~241HBW.

Tempering treatment

Quenching temperature 880~890°C, oil cooling, tempering temperature 680~700°C, hardness 197~229HBW.

Ordinary quenching and tempering

- 1) Quenching temperature 830~860°C. Oil cooling, hardness 62~64HRC, tempering temperature 150~200°C, hardness 61~63HRC.

- 2) Quenching temperature varies from 850 to 870℃. Oil cooling, hardness 62-65HRC, tempering temperature 140-160, hardness 62-65HRC.

- 3) Quenching temperature 850 ~ 870°C. Oil cooling, hardness 62-65HRC, tempering temperature 160 ~ 180°C, hardness 61-63HRC.

- 4) Preheating temperature 450~500°C. quenching temperature 870~880°C. Oil cooling, tempering temperature 180~200°C. holding for 2h, hardness 59~62HRC.

Application

9SiCr alloy tool steel can be used to manufacture tools with small deformation, high wear resistance and low-speed cutting. Such as drill bits, thread tools, reamers, dies, taps, thread rolling plates and thread rolling wheels. When used as plastic mold steel, it can be used for ejector rods to manufacture plastic films with enlarged sizes, complex shapes and high precision requirements.

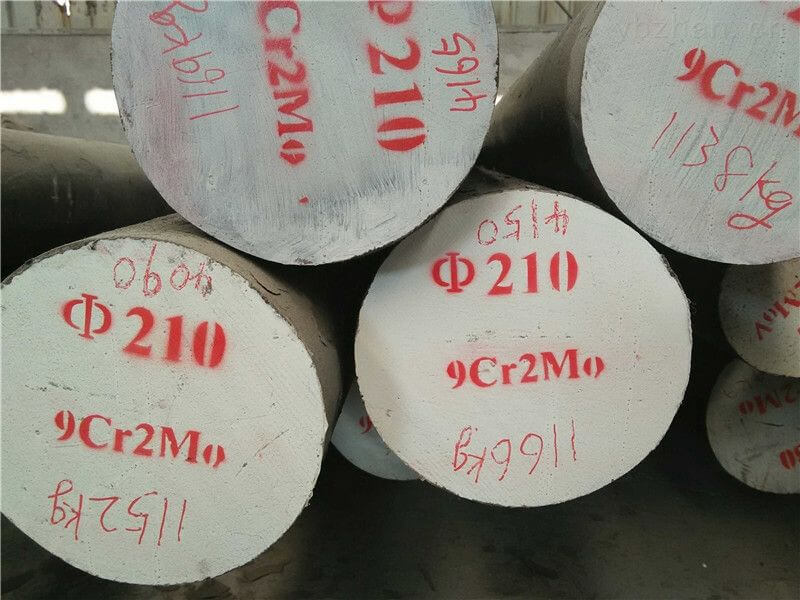

9SiCr products

| Product type | Products | Dimension | Processes | Delivery Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging,hot rolling and cold rolling | Annealed, Solution and Aging, Q+T,ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar,Flat Bar,Square Bar | Φ8-1200mm*L | Forging,hot rolling and cold rolling,Cast | Black,Rough Turning,Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed,Solution and Aging,Q+T,ACID-WASHED,Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes,Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion,Cold Drawn,Welded | Annealed,Solution and Aging,Q+T,ACID-WASHED |