Description

Cr14Mo4V is molybdenum-containing high-grade steel, but also the world’s most widely used in high-temperature bearing steel, in addition to general bearing characteristics, but also has high dimensional stability, high-temperature hardness, high-temperature contact fatigue performance, Long-term use at temperatures below 315 ℃.

Cr14Mo4V Steel Material Chemical Composition

| C | Si | Mn | S | P | Cr | Ni | Cu | V | Mo |

| 0.75~0.85 | ≤0.35 | ≤0.35 | ≤0.020 | ≤0.027 | 3.75 ~ 4.25 | ≤0.20 | ≤0.20 | 0.90 ~ 1.10 | 4.00 ~ 4.50 |

Mechanical property

Impact energy Akv (J): 9.8

Hardness: 65hrc

Heat treatment

heat preservation at 1110 ± 5 ℃ for 15 ~ 20min and quenching; Preheat at 860 ℃ and temper at 530 ℃ for 3 times, 2h each time.

Features and Application

It has high dimensional stability at high temperature, high temperature hardness and high temperature contact fatigue performance. It is mainly used as aeroengine bearing and other high temperature resistant bearings.

Available Size

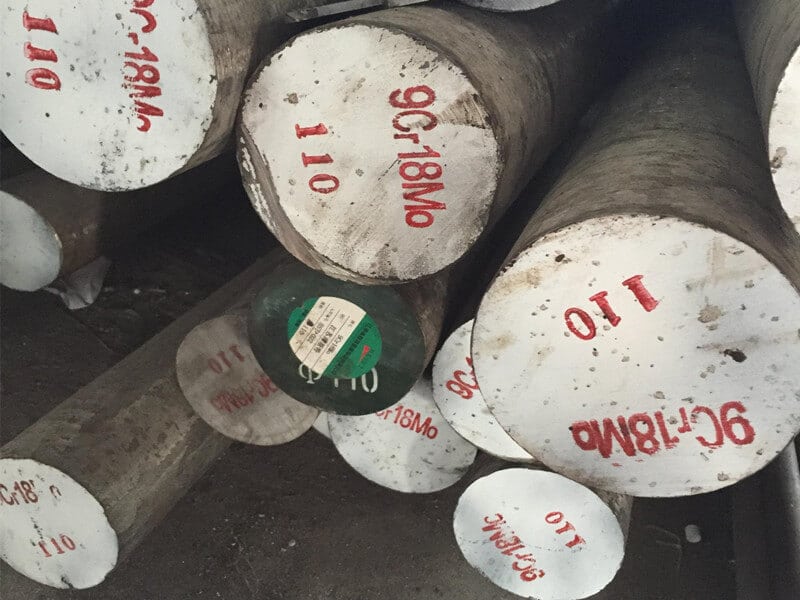

| Round Bar | Diameter(mm): 6-800mm ,Length: 1000-9000mm or custom size |

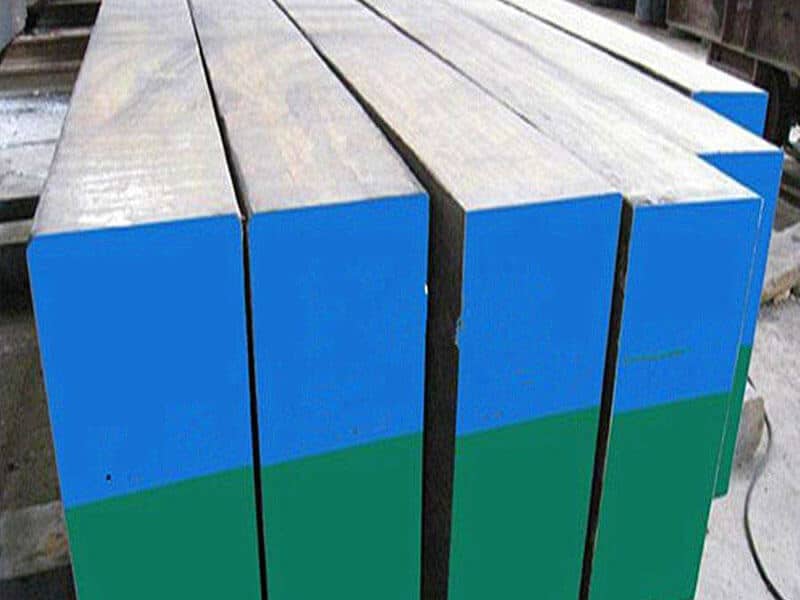

| Plate/Flat/Block | Thickness: 6mm-500mm , Width: 20mm-1000mm or custom size |

| Tolerance | ±1%,Thickness: +/-0.02mm, Width:+/-2mm |