Description

Cr5Mo1V is air-quenched mold steel. This is extremely beneficial for complex molds that must retain their shape after quenching and tempering.

The deformation of this steel due to air quenching is only about 1/4 of that of manganese-containing oil-quenched tool steel. The wear resistance is between manganese type and high carbon and high chromium type tool steel. Its toughness is better than anyone. It is especially suitable for tools that require good wear resistance and special toughness. Widely used in blanking and forming dies, rolls, punches, calendering dies and rolling dies. Also used for scissors.

Cr5Mo1V equivalents

| / | China | EU | Germany | Japan | France | England | USA |

| Standard | GB | EN | DIN,WNr | JIS | AFNOR | BS | – |

| Grade | Cr5Mo1V | X100CrMoV5 (1.2363) | X100CrMoV5-1 | SKD12 | Z100CDV5 | BA2 | A2 |

| / | Poland | Czechia | Austria | Russia | Inter | Italy | Sweden |

| Standard | PN | CSN | ONORM | GOST | ISO | UNI | SS |

| Grade | NCLV | 19571 | K305 | 9KH5VF | X100CrMoV5 | X100CrMoV5-1KU | 2260 |

Chemical Composition

| C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Mo(%) | V(%) | Cu(%) |

| 0.95~1.05 | ≤0.50 | ≤1.00 | ≤0.030 | ≤0.030 | 4.75~5.50 | ≤0.20 | 0.90~1.40 | 0.15~0.50 | ≤0.30 |

Cr5Mo1V Mechanical Properties

| Proof strength Rp0.2(MPa) | Tensile strength Rm(MPa) | Impact energy KV(J) | Elongation at fracture A(%) | Reduction in cross section on fracture Z(%) | As-Heat-Treated Condition | Brinell hardness(HBW) |

| 828(≥) | 147(≥) | 21 | 44 | 22 | Solution and Aging,Annealing,Ausaging,Q+T,etc | 221 |

Cr5Mo1V Physical Properties

| Temperature (°C) | Modulus of elasticity (GPa) | Mean coefficient of thermal expansion 10-6/(°C) between 20(°C) and | Specific thermal capacity (J/kg·°C) | Specific electrical resistivity (Ω mm²/m) | Density (kg/dm³) | Poisson’s coefficient, ν | Thermal conductivity (W/m·°C) |

| 22 | – | – | 0.32 | – | |||

| 251 | 588 | – | 214 | – | 42.3 | ||

| 173 | – | 21 | 432 | 431 | 41.2 |

Heat Treatment

Annealing: 1) Slow cooling at 800-850oc 2) Spheroidizing annealing process

Tempering: 180-220oc air cooling. HRC = 60-64 510-520oc air cooling HRC = 57-60

Application

- It is used to form elastic steel sheets with a carbon content of 0.65% to 0.80%. The hardness is 37~42HRC, and the service life can reach 110,000~120,000 times. With additional nitriding treatment, the service life can reach 400,000 times.

- The steel is used for wire rolling die. For machining aluminum and copper alloys.

- It is suitable for making forming dies, blanking dies and cold blanking dies.

- It is used to make drill sleeves, punches, trimming dies and thread rolling dies.

- For wear-resistant plastic molds.

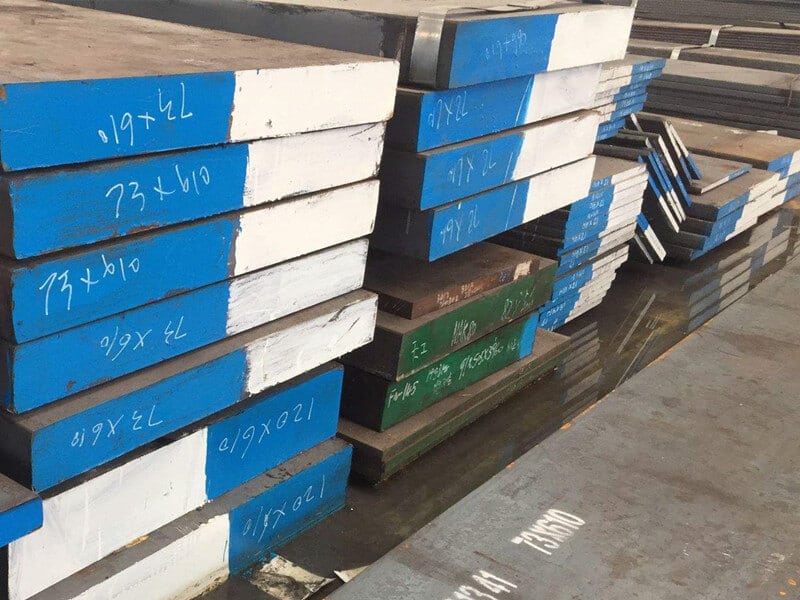

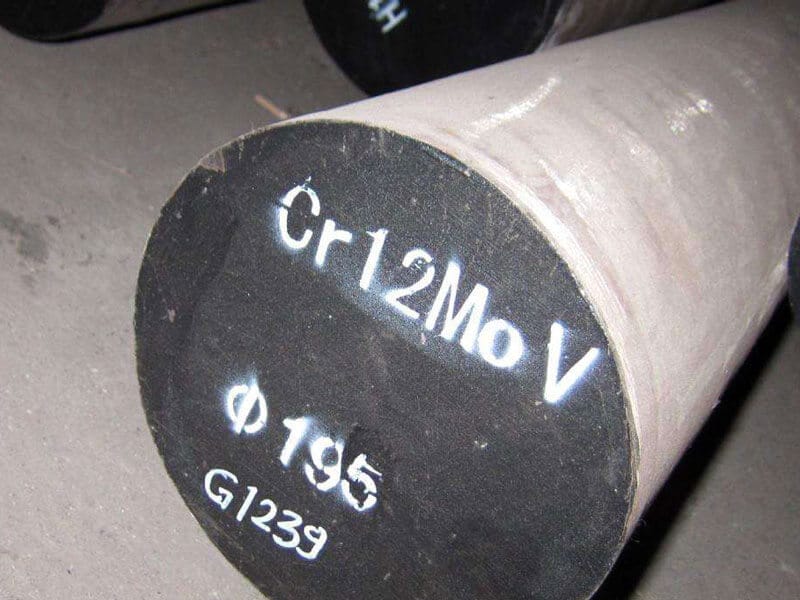

Cr5Mo1V products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging,hot rolling and cold rolling | Annealed,Solution and Aging, Q+T,ACID-WASHED,Shot Blasting |

| Steel Bar | Round Bar,Flat Bar,Square Bar | Φ8-1200mm*L | Forging,hot rolling and cold rolling,Cast | Black,Rough Turning,Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed,Solution and Aging, Q+T,ACID-WASHED,Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes,Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion,Cold Drawn,Welded | Annealed,Solution and Aging, Q+T,ACID-WASHED |