Description

T7 (A) high toughness carbon tool steel. Cold work mold steel or Die steel. The steel has good toughness, good chip machinability, low price and easy source.

T7 Worldwide Equivalents

| country / region | China | EU | Germany | Japan | France | Italy |

| Standard | GB | EN | DIN,WNr | JIS | AFNOR | UNI |

| Grade | T7 | C70U (1.1520) | 1.1620 C70W2 | SK6 SK7 | C70E2U | C70KU |

| country / region | Poland | Czechia | Austria | Russia | Inter | |

| Standard | PN | CSN | ONORM | GOST | ISO | |

| Grade | N7 | 19132 | K970 | U7 | C70U |

Chemical Composition

| C | Si | Mn | S | P | |

| % | 0.65-0.74% | 0.35% MAX | 0.40 % MAX | 0.03% MAX | 0.035% MAX |

Features

The hardenability and wear resistance is low. The shrinkage of the cavity during quenching is weak, and the quenching deformation is large.

Poor tempering stability.

The quenching depth is water quenching 15-18mm.

Oil quenched 5-7mm. It is suitable for making small pieces that are easy to quench and break. Large pieces are prone to arc cracks due to the shallow hardened layer.

T7 Steel Physical properties

Critical temperature

| Critical point | Ac1 | Ac3 | Ar1 |

| Temperature/℃ | 730 | 770 | 700 |

Expansion coefficient

| Temperature/℃ | 20~100 | 20~200 | 20~300 | 20~400 |

| Expansion coefficient/℃-1 | 11.8×10-6 | 12.6×10-6 | 13.3×10-6 | 14.0×10-6 |

Thermal conductivity

| Temperature/℃ | 20 | 100 | 300 |

| Coefficient of thermal conductivity,λ/W·(m·K)-1 | 44.0 | 44.0 | 41.9 |

Heat treatment specification

Normalizing

Temperature 800-820℃, air-cooled, hardness 229-285HBS

Ordinary annealing(740-750)℃×(2-4)h. With a cooling rate of <30℃/h, slowly furnace-cooled to a temperature of 500-600℃, and air-cooled after being released from the furnace.

Isothermal spheroidizing annealing

- 1. (740-750) ℃ × (2-4) h. (650-680) ℃ × (4-6) h, after furnace cooling to 500-600 ℃, air cooling, hardness ≤ 187HBS.

- 2. (750-770) ℃ × (1-2) h. (680-700) ℃ × (2-3) h, after furnace cooling to 500-600 ℃, air cooling, hardness 163-187HBS.

Quenching, tempering

Quenching temperature 730-760℃. Water cooling, water-oil double-liquid cooling or alkali bath cooling. Quenching hardness 57HRC. Tempering temperature 160-180℃.

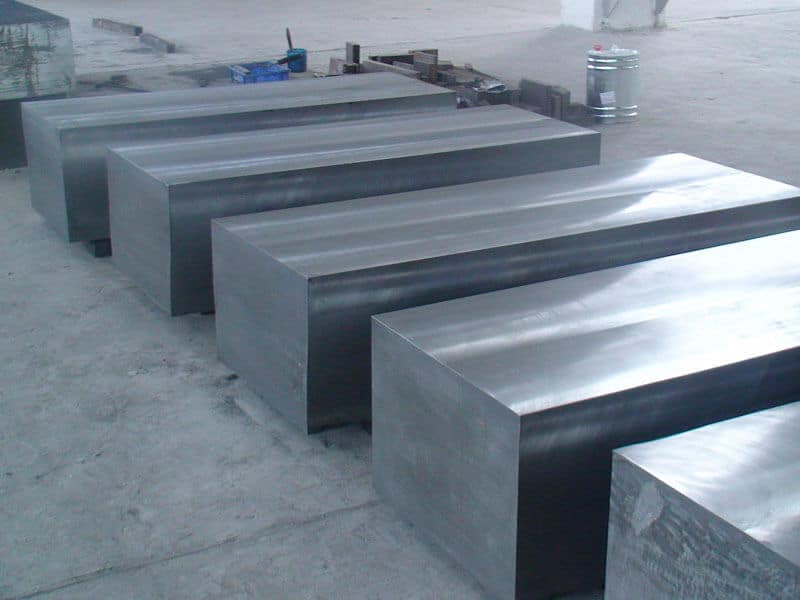

Available Size

| Round Bar | Diameter(mm): 6-800mm ,Length: 1000-9000mm or custom size |

| Plate/Flat/Block | Thickness: 6mm-500mm , Width: 20mm-1000mm or custom size |

| Tolerance | ±1%,Thickness: +/-0.02mm, Width:+/-2mm |

T7 Steel Application

- Cold work mold with small size, simple shape and light load. For example, small punch.

- Scissors for cutting steel plates.

- It is suitable for making cold working molds that require not deep hardened layer and maintain high toughness.

- Hex nut cold heading die T7A. Recommended hardness 48-52HRC.

- It is suitable for all kinds of molds produced in small and medium batches.

- Mold for impact load.