Description

Cr12W is a wear-resistant cold work mold steel. It has the characteristics of high hardenability, hardenability, toughness, wear resistance, and small quenching volume deformation.

Cr12W Worldwide equivalents grade

| / | China | England | Germany | Japan |

| Standard | GB | BS | DIN,WNr | JIS |

| Grade | Cr12W | BS1 | 1.2436 x210Crw12 | SKD2 |

| / | Italy | Spain | Austria | Sweden |

| Standard | UNI | UNE | – | ASSAB/SS |

| Grade | X215CrW121KU | x21oCrW12 | K107 | Xw5/ 2710 |

Cr12W Steel Chemical Composition(%)

| C | Si | Mn | S | W | Cr | P |

| 2.0-2.3 | ≤0.40 | ≤0.35 | ≤0.03 | 0.6-0.9 | 11.0-12.5 | ≤0.03 |

Heat Treatment

Annealing

800 to 850°C

Slow controlled cooling in the furnace at a rate of 10 to 20°C/hr down to approx. 600°C, further cooling in air.

Hardness after annealing: max. 250 HB

Stress relieving

650 to 700°C

Slow cooling in furnace; intended to relieve stresses set up by extensive machining, or incomplex shapes.

After heating, hold in a neutral atmosphere for 1 to 2 hours.

Hardening

950 to 980°C

Oil, salt bath (220 to 250°C or 500 to 550°C), air plast, still air. Holding time after temperature equalization: 15 to 30 minutes. Obtainable hardness: 64 – 66 HRC.

Special treatment: Hardening 1020°C and tempering at 500°C.

Obtainable hardness approx. 61 HRC (e.g. if followed by nitriding).

Tempering

Slow heating to tempering temperature immediately after hardening/time in furnace 1 hour for each 20 mm of workpiece thickness but at least 2 hours/cooling in air. For certain cases we recommend reducing tempering temperature and increase holding time.

Features and Application

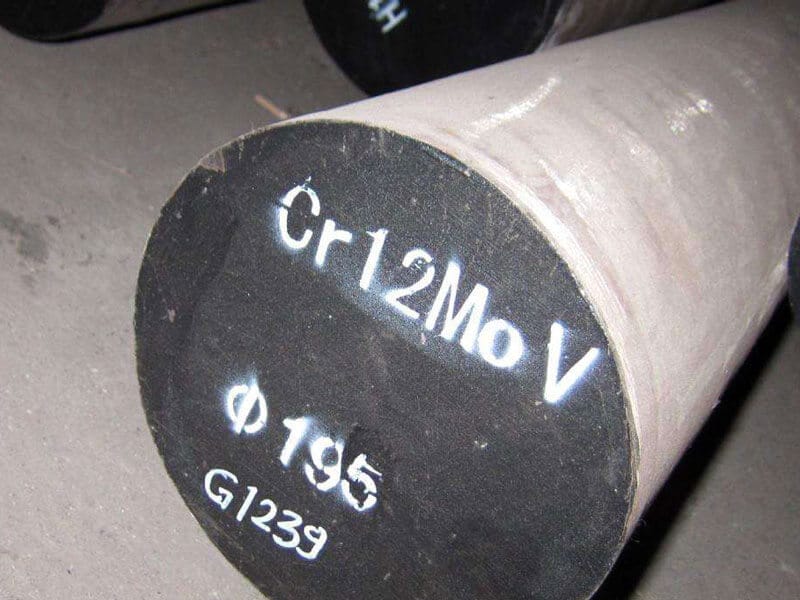

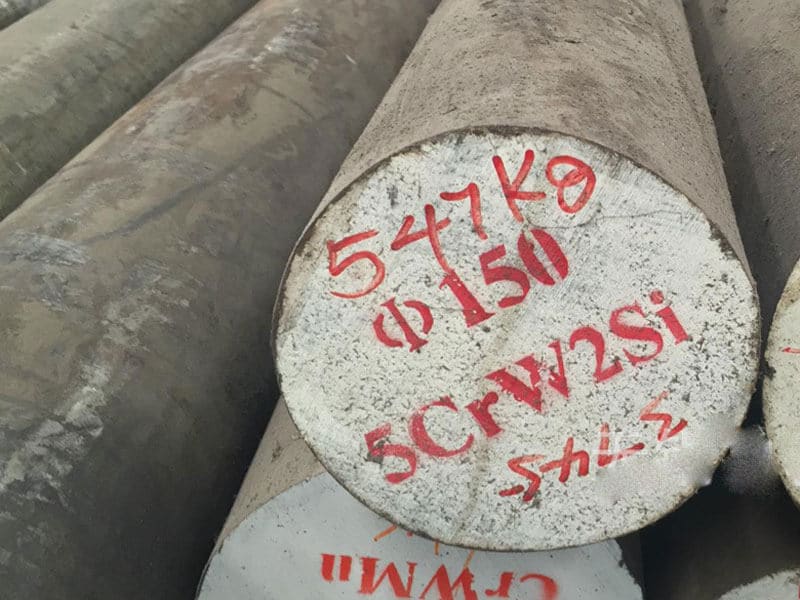

Available Size

| Round Bar | Diameter(mm): 6-800mm ,Length: 1000-9000mm or custom size |

| Plate/Flat/Block | Thickness: 6mm-500mm , Width: 20mm-1000mm or custom size |

| Tolerance | ±1%,Thickness: +/-0.02mm, Width:+/-2mm |

Our Services

1. The price is determined according to the material, size, finishing process and different payment methods

2. Each material has been ut tested

3. We have every kind of material in stock, so we can deliver it in time.

4. The size of steel can be customized according to customer requirements, and the minimum order quantity and specification model can be developed / produced according to international, Chinese or industrial standards

5. There are more services. Welcome to consult.