Description

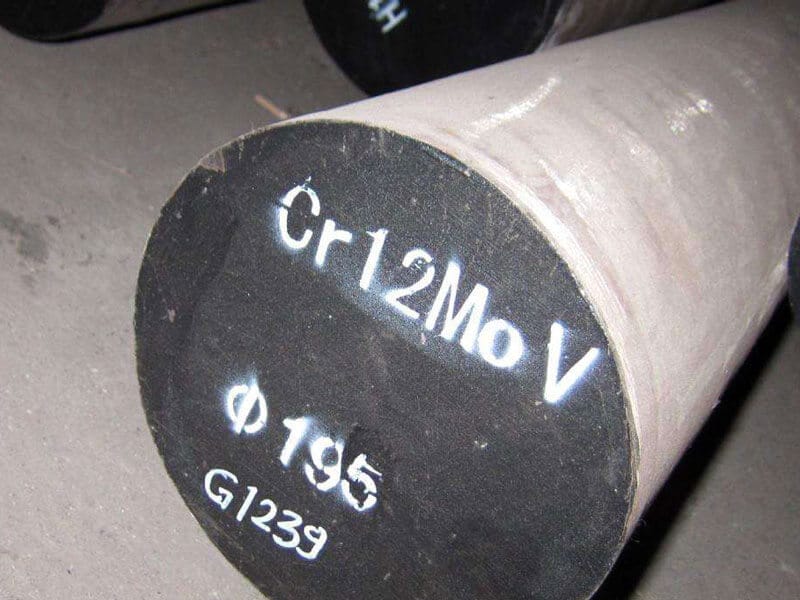

Cr4W2MoV steel is a new type of medium alloy steel cold work die steel. Its performance is relatively stable. The service life of its mold is greatly improved than that of Cr12 and Cr12MoV steel.

Cr4W2MoV Worldwide Equivalents

| / | China | Italy | Germany | USA | South Korea | Russia |

| Standard | GB | UN1 | DIN,WNr | AISI / SAE | Ks | roCT |

| Grade | Cr12Mov | x165CrM0W12KU | SKD11/1.2601 | D2 | STD11 | X12M |

Cr4W2MoV Chemical Composition

| C | Si | Mn | Cr | W | Mo | V | P | S |

| 1.12~ 1.25 | 0.40~ 0.70 | ≤0.40 | 3.50~ 4.00 | 1.90~ 2.00 | 0.80~ 1.20 | 0.80~ 1.10 | ≤0.030 | ≤0.030 |

Mechanical Propoerties

| Yield Strength Rp0.2(MPa) | Tensile Strength Rm(MPa) | Impact Energy AKV(J) | Elongation at Fracture A(%) | Reduction in Cross Section on Fracture Z(%) | Impact toughness value αkv (J/cm2) | Hardness(Brinell) |

| ≥ 902(85) | ≥ 941(100) | ≥ 24 | ≥ 41 | ≥ 23 | ≥ 88 | ≤ 431 |

Physical Properties

Critical temperature of Cr4W2MoV steel

| critical point | Ac1 | Acm | Ar1 | Ms |

| Temperature (approximate) / ℃ | 795 | 900 | 760 | 142 |

Heat Treatment:

The steel is difficult to soften by annealing. Generally, isothermal spheroidizing annealing is used.

Annealing Process:The heating temperature is 850~870 degrees, and the heat preservation is 4~6H. The isothermal temperature is 760 degrees, the heat preservation is 6~8H, the furnace is cooled to below 600 degrees, and the hardness is 229HBW.

Quenching heating temperature is 960~980 degrees, oil cooling or air cooling, hardness 62HRC.The tempering temperature is 280~300 degrees, and the tempering is performed 3 times, 1H each time. Tempering hardness 60~62HRC.

The mold with High temperature quenching and tempering (1030 degree quenching, 520 degree tempering three times has high wear resistance and hot hardness

The mold with low-temperature quenching and tempering (quenching at 900~980 degrees, tempering at 200~290 degrees) has good toughness.

Features and Application

The main feature of Cr4W2MoV steel is that the eutectic carbide particles are fine and evenly distributed. Has high hardenability and hardenability. Has better wear resistance and dimensional stability.

The steel has a narrow hot working temperature range. Deformation resistance is large. The actual use proves that Cr4W2MoV steel is a cold work die steel with good performance. It can manufacture various punching dies, cold heading molds, blanking molds, cold extrusion molds, and wire-setting plat

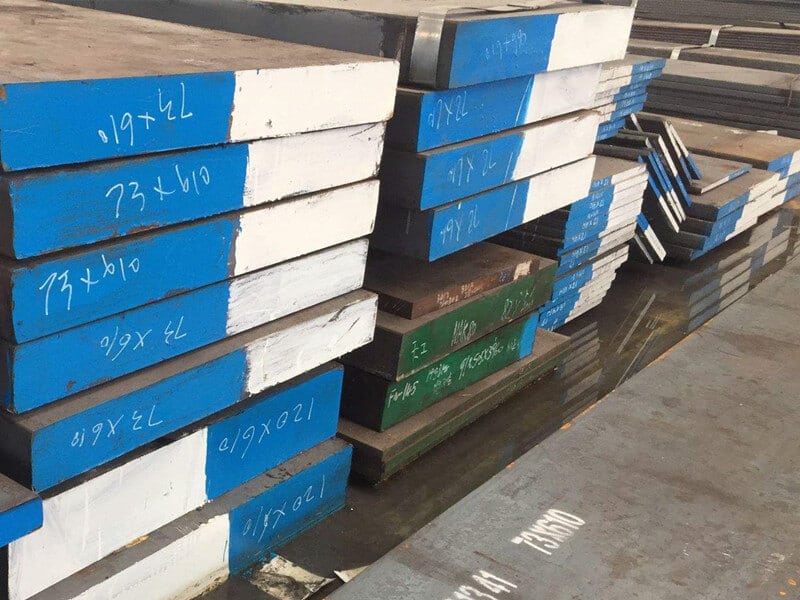

Available Size

| Round Bar | Diameter(mm): 6-800mm ,Length: 1000-9000mm or custom size |

| Plate/Flat/Block | Thickness: 6mm-500mm , Width: 20mm-1000mm or custom size |

| Tolerance | ±1%,Thickness: +/-0.02mm, Width:+/-2mm |