Description

SM50 steel is a carbon plastic mold steel. Its chemical composition is similar to that of high-strength medium-carbon high-quality structural steel-50 steel. However, the cleanliness of the steel is higher, the fluctuation range of carbon content is narrower, and the mechanical properties are more stable. The steel has certain hardness, strength and wear resistance after normalizing or quenching and tempering. The price is cheap and the cutting performance is good.

SM50 Steel Chemical Composition

| C | Si | Mn | P | S |

| 0.47~0.53 | 0.17~0.37 | 0.50~0.80 | ≤0.030 | ≤0.030 |

SM50 Steel Mechanical Properties

| Proof strength Rp0.2(MPa) | Tensile strength Rm(MPa) | Impact energy KV(J) | Elongation at fracture A(%) | Reduction in cross section on fracture Z(%) | As-Heat-Treated Condition | Brinell Hardness(HBW) |

| 521(≥) | 756(≥) | 12 | 11 | 23 | Solution and Aging,Annealing,Ausaging,Q+T,etc | 313 |

SM50 Steel Physical Properties

| Property | Density kg/dm3 | Temperature T °C/F | Specific heat J/kgK | Modulus of elasticity kN/mm2 |

| 959(≥) | 283(≥) | 33 | 33 | 114 |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0)N/mm2 | Creep rupture strength (10000h) (Rp1,0)N/mm2 | Thermal conductivity W/mK | Electric resistance µΩ·cm |

| 734 | 895 | 813 | 32 | Solution and Aging,Annealing,Ausaging,Q+T,etc |

Heat Treatment

Critical temperature of SM50 steel

| Critical point | Ac1 | Ac3 | Ar3 | Ar1 |

| Temperature (approximate) / ℃ | 725 | 760 | 720 | 690 |

Fully annealed

Heating at 810~830℃. Insulation, furnace cooling, hardness is 197~225HBS. The heating temperature is above the Ac3 line to get the pearlite + ferrite structure

Normalizing

Heating at 820~870℃. Heat preservation, air cooling, hardness is 217~248HBS, heating temperature is above the Ac3 line, refine grains, eliminate structural defects, and get pearlite + a small amount of ferrite structure

Quenching

Heating at 820~850℃. Insulation, water-oil cooling, hardness is 55~58HRC. Water cooling prevents tissue transformation at high temperatures and reduces thermal stress. Oil cooling reduces phase transformation stress and prevents deformation and cracking

Tempering

Heating at 200~600℃. Heat preservation for 2h, air cooling, hardness is 23~56HRC.

| Tempering temperature/℃ | 200 | 300 | 500 | 550 | 600 |

| Tempering hardness/HRC | 56 | 51 | 42 | 33 | 23 |

Features and Application

SM50 alloy steel is high-strength medium-carbon steel. It has low cold deformation plasticity, poor weldability and hardenability. But, it has no temper brittleness and general cutting performance. Use under normalizing or quenching and tempering. It is used to manufacture machined parts and spring parts with little dynamic load and impact. Such as forged gears, tie rods, rolls, shafts, friction discs, agricultural excavation ploughshares, heavy duty mandrels.

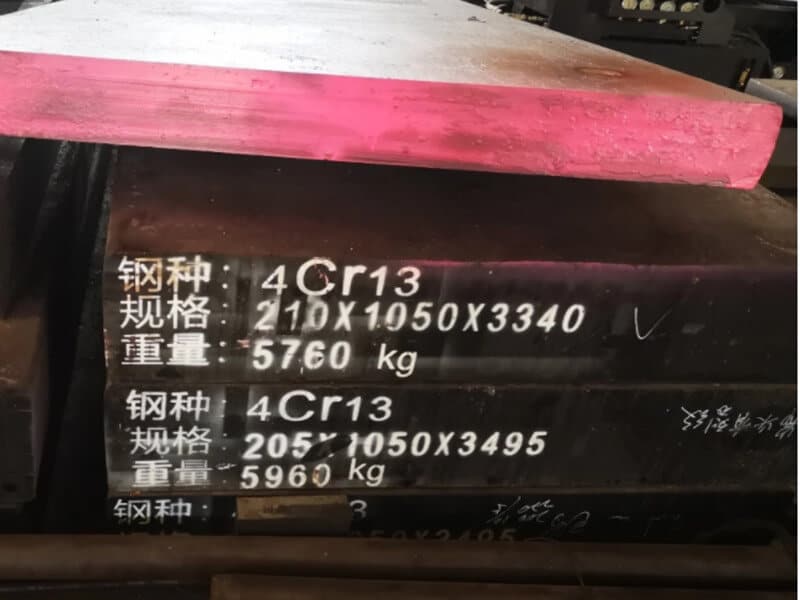

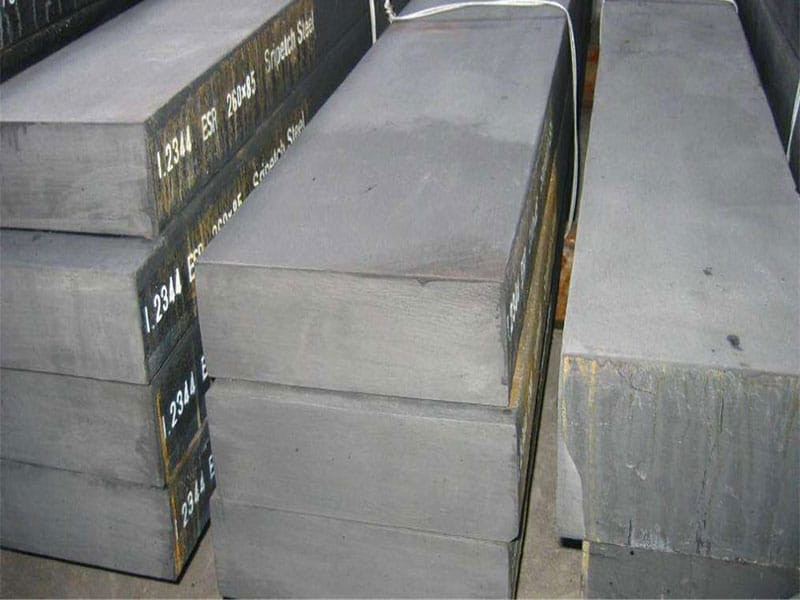

SM50 Products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |