Description

T8 Steel belongs to carbon tool steel. Hardened plastic mold steel. After quenching and tempering, it has higher hardness and wear resistance. But, it has a low hot hardness, poor hardenability, easy deformation, plasticity and low strength.

T8 Steel Chemical Composition

| C | Si | Mn | S | P | Cr | Mo | V | W | Co |

| 0.75-0.85 | 0.20-0.40 | 0.20-0.40 | ≤0.030 | ≤0.030 | 3.75-4.50 | 0.4-1.00 | 1.8-2.4 | 13.25-14.75 | 4.25-5.75 |

T8 Steel Mechanical Properties

| Proof strength Rp0.2 (MPa) | Tensile strength Rm (MPa) | Impact energy KV (J) | Elongation at fracture A (%) | Reduction in cross section on fracture Z (%) | As-Heat-Treated Condition | Brinell hardness (HBW) |

| 564 (≥) | 191 (≥) | 32 | 21 | 12 | Solution and Aging, Annealing, Ausaging, Q+T | 341 |

T8 Physical properties

| Property | Density kg/dm3 | Temperature T °C/F | Specific heat J / kgK | Thermal conductivity W/mK |

| 129 (≥) | 823 (≥) | 23 | 42 | 31 |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0) N/mm2 | Creep rupture strength (10000h) (Rp1,0) N/mm2 | Electric resistance µΩ·cm | Modulus of elasticity kN/mm2 |

| 973 | 572 | 558 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 433 |

Features and Application

T8 steel is used for various tools that need high hardness and wear resistance. Such as simple-shaped dies and punches, metal cutting knives. Drilling tools, woodworking cutters, countersinks, axes, chisels, longitudinal hands Use saws. Fitter assembly tools, rivet dies. It is not easy to make tools that can withstand large impacts.

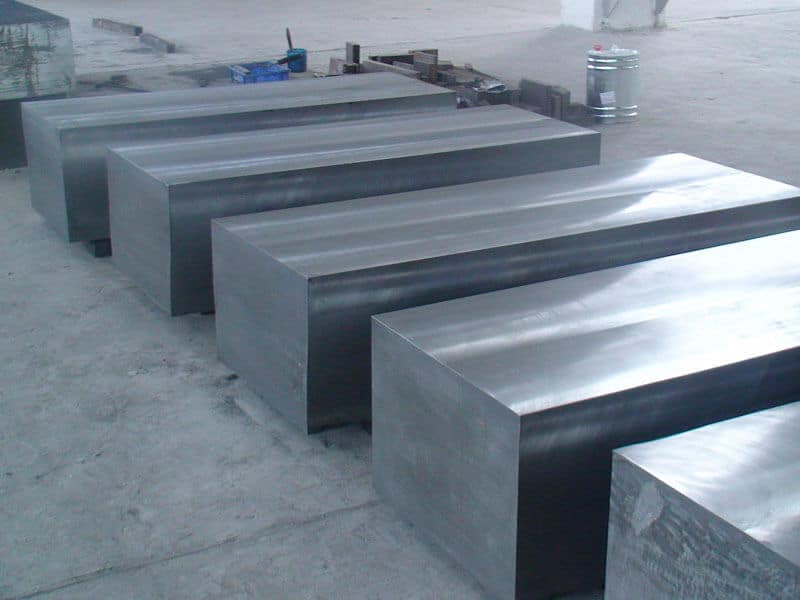

T8 products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

Our Services

1. The price is determined according to the material, size, finishing process and different payment methods

2. Each material has been ut tested

3. We have every kind of material in stock, so we can deliver it in time.

4. The size of steel can be customized according to customer requirements, and the minimum order quantity and specification model can be developed / produced according to international, Chinese or industrial standards

5. There are more services. Welcome to consult.